CMT: Customized Mastery Tailored by Clothing Manufacturers

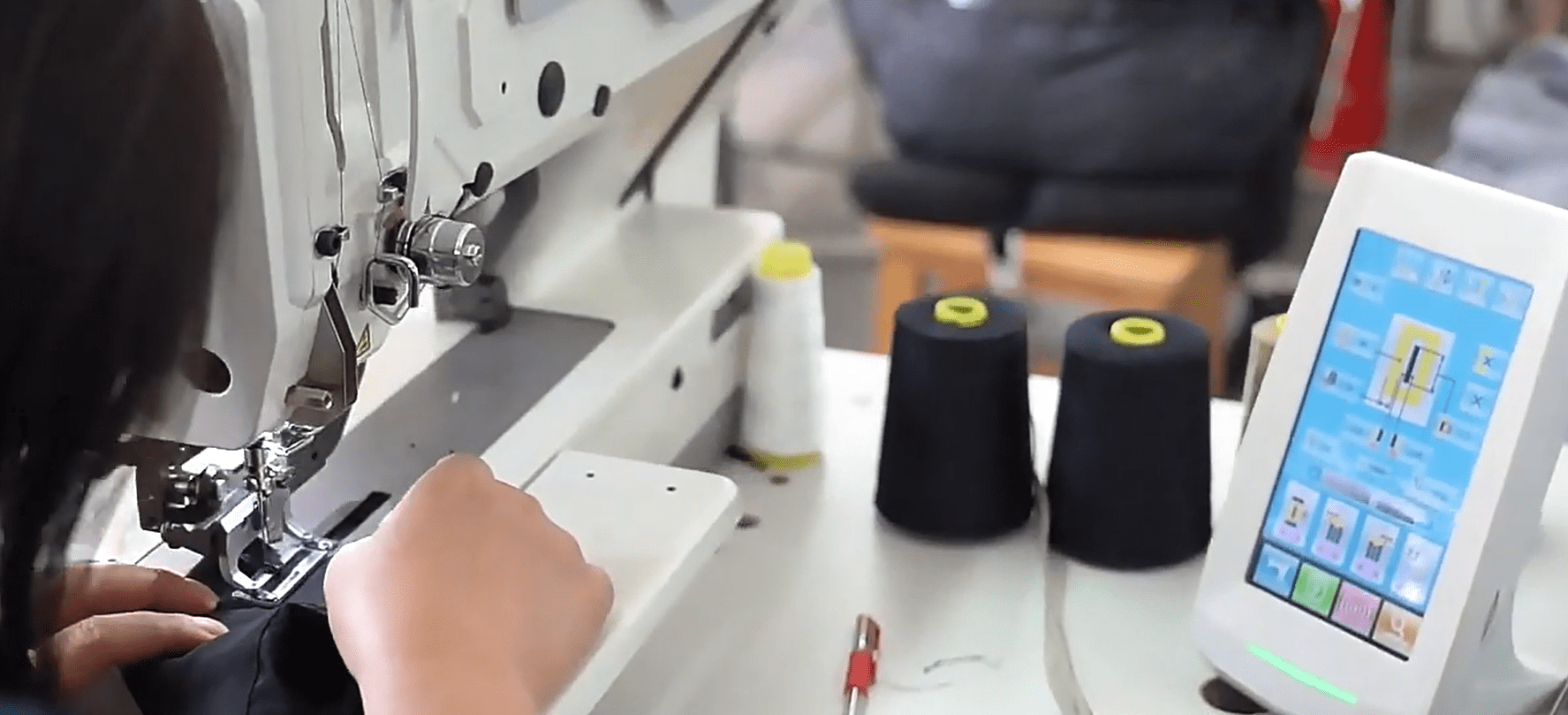

CMT clothing manufacturers stand as an integral part of the textile industry, assuming the vital responsibility of transforming fabric into stylish wearable items. These industry professionals bring the latest fashion trends and designs to light via an extensive process that balances practicality, trendiness, and affordability. With their expert knowledge, CMT manufacturers use a range of techniques in clothing production, often specialized to deliver their client’s unique requests.

As a clothing manufacturer in the CMT or ‘Cut-Make-Trim’ sector, the process involves the steps of designing, cutting, making, and trimming garments as per specific instructions from fashion designers or clothing brands. The clothing manufacturer ensures the efficient and effective conversion of fabrics into final clothing products, maintaining the quality, integrity, and functionality of the pieces. Their expertise in the specific dynamics of CMT manufacturing ensures agility in the face of changes in fashion trends and consumer demands.

The Process of Customizing Clothes in Garment Manufacturing

Customization in the garment manufacturing sector holds significant importance. It goes beyond just putting together fabrics and threads. Instead, it incorporates innovative designs and unique style elements to create personalized clothing. As a crucial step in this process, the garment manufacturer plays a vital role in converting raw materials into finished customized garments. They make it possible to transform an idea into something physical and wearable, harmonizing aesthetics and comfort to meet the specific needs of individual clients.

Pjgarment.com, being a leading name in this sector, tailors their services to satisfy the varying demands of their clientele. With diverse customization offerings including patterns, styles, fits, and fabrics, they make it possible for anyone to be their own designer. Their skilled artisans and state-of-the-art technology ensure the delivery of high-quality, custom apparel. Special emphasis is put on precision and detailing which helps in crafting garments that align meticulously with the customer’s vision. In this ever-evolving fashion industry, such dedicated customization processes are key to standing out and staying relevant.

The Art of Mastery in Clothing Manufacturing Companies

In the arena of fashion and apparel production, achieving a degree of mastery is no elementary endeavor. It demands unparalleled proficiency, keen attention to the finer details, and a deep-rooted understanding of the trends shaping the industry. This is vividly illustrated in the operations of London clothing manufacturers who are globally acclaimed for their meticulous attention to design, quality and innovative approach to fashion.

Among the many factors shaping the realm of clothing manufacturing, CMT manufacturing near me has emerged as a crucial paradigm. This model calls for Cut, Make, and Trim – each component playing a vital role in the final output of exceptional clothing items. The fusion of advanced technology, refined craftsmanship, and the adoption of sustainable practices distinguishes the true masters in clothing manufacturing from the ordinary. It is the dedication to these principles, along with a steady focus on customer requirements, that set the stage for a truly memorable fashion experience for the end consumer.

• Cut: The first step in the CMT manufacturing process is cutting. This involves precision and expertise to ensure that each piece of fabric is cut accurately according to the design specifications. It requires a deep understanding of patterns, measurements, and the properties of different fabrics.

• Make: This stage brings together all the individual components into a cohesive whole. It demands skilled craftsmanship and an eye for detail to ensure that every seam, stitch, and embellishment aligns perfectly with the original design concept.

• Trim: Trimming refers to any final adjustments or finishing touches required before a garment is ready for sale. This could include anything from attaching buttons or zippers to adding decorative elements like embroidery or beadwork.

The clothing manufacturing industry’s mastery lies not only in these three steps but also in their integration – how seamlessly they flow into one another under expert guidance.

• Advanced Technology: The use of advanced technology plays a pivotal role in enhancing efficiency while maintaining high-quality standards across all stages of production. From computer-aided design (CAD) tools used during the planning phase to automated sewing machines ensuring uniform stitching quality – technology acts as an enabler of excellence.

• Refined Craftsmanship: Despite technological advancements, human skills remain irreplaceable when it comes down to nuanced details such as draping techniques, hand-stitched finishes etc., which contribute significantly towards creating unique pieces that stand out on global fashion platforms.

• Sustainable Practices: With increasing environmental consciousness among consumers worldwide today’s leading clothing manufacturers prioritize sustainable practices like using eco-friendly materials and minimizing waste throughout their operations without compromising on style or quality.

In conclusion, achieving mastery within clothing manufacturing companies calls for more than just technical knowledge; it necessitates dedication towards continuous improvement driven by customer needs while staying true to sustainability principles – thus delivering truly memorable fashion experiences time after time.

The Significance of Tailoring in Fashion Industry

Tailoring provides the backbone to all clothing manufacturing companies, acting as a foundation on which their stellar couture artistry is built. As the crux of fashion production processes, tailoring requires unique craftsmanship and expertise. This hands-on manual work involves giving shape and form to fabric, transforming it into a garment that fits perfectly to the body of the wearer. This process is nothing less than an art form, where minute details in design and precision reflect the identity and vision of the brand.

The role of tailoring can not be understated in the CMT scenario in the garment industry. CMT, which stands for Cut, Make, and Trim, is an integral model in clothing manufacturing where tailoring plays the central role in meeting aesthetic quality and fitting standards. CMT is a commonly used practice where clothing manufacturing companies can keep the cost of production down while maintaining high-quality standards. As a crucial part of the fashion industry, tailoring helps in implementing fine precision, thereby leading to trends that echo the brand’s philosophy and maintaining the industry’s dynamics.

The Impact of Customization on Apparel Manufacturing

Rapid advancements in technology, coupled with evolving consumer preferences, have led to a significant shift in the traditional practices of apparel manufacturing. Customization has emerged as a potent tool, enabling clothing brands to create unique, personalized experiences for their customers. Especially relevant to CMT apparel production, customization offers unparalleled versatility and flexibility, allowing brands to cater to a diverse array of styles, sizes, and preferences, contributing to the industry’s thriving dynamic.

At the forefront of this trend are Canadian clothing manufacturing companies, which have adeptly integrated advanced technologies with CMT processes to offer a wide variety of customization options. Their profound understanding of the consumer’s increasing inclination towards personalized clothing has helped shape customizable product offerings. Given the capability to adapt quickly and efficiently to market changes, these companies have been successful in capturing considerable market attention. Thus, customization in apparel manufacturing is not merely a trend but a profound, impactful strategy reshaping the contours of the industry.

Exploring the Benefits of CMT Apparel Production

In the highly competitive garment industry, CMT (Cut, Make, Trim) apparel production offers several pivotal benefits. This method of clothing production is proving to be a game-changer, especially for emerging designers and small-scale retailers seeking efficient, cost-effective solutions. Engaging with reputable CMT clothing manufacturers maximizes profitability by reducing overhead and minimizing the required investment for factories, equipment and labour force.

A prime example of this model’s efficacy is the thriving industry of CMT clothing manufacturers in South Africa. Here, manufacturers are known for offering high-quality outputs, time efficiency, and commendable attention to detail, all while keeping manufacturing costs low. This has not only boosted their domestic market but has also attracted a substantial international clientele, underscoring the contribution of CMT apparel manufacturing to the global garment industry’s evolution.

Steps Involved in CMT Clothing Production

The CMT (Cut, Make, Trim) method of apparel production constitutes a significant facet of the textile industry. This model represents a strategic business decision for fashion brands, especially those looking to outsource parts of their production cycle. Within this frame, an understanding of the steps involved in CMT clothing production becomes imperative.

The initial phase, cutting, requires precise pattern cutting in accordance with the design of the garment. This intricate task sets the foundation for the entire structure, making it a crucial operation. As the term suggests, the make stage is where each piece is meticulously sewn together to form the garment. The final stage, trim, involves adding the finishing touches to the product such as buttons, zippers, or embellishments, finalizing the look of the garment. Thus, a clear comprehension of each stage in the CMT clothing production process can lead to greater efficiency and quality in apparel production.

Challenges Faced by Clothing Manufacturing Companies

In an increasingly competitive global market, clothing manufacturing companies confront a myriad of challenges. One significant issue is sustaining optimum quality while also ensuring affordability. This balancing act becomes all the more complex when considering economic fluctuations, cost of raw materials, and import/export tariffs. Moreover, increasingly conscious consumers demand ethically and sustainably produced garments, bringing an added layer of complexity to the production process.

In addition to these factors, technological advancement presents both opportunities and challenges for clothing manufacturers. While it undoubtedly enhances efficiency and allows for more detailed customization, integrating these technologies into existing infrastructures requires substantial investment. Plus, inevitable technical hiccups and the necessity of upskilling staff members also add to the potential hurdles. All the while, manufacturers must keep pace with rapid fashion trends, juggling all these balls without allowing their standards or delivery times to slip.

How CMT Apparel Manufacturing is Reshaping the Fashion Industry

In the contemporary fashion arena, CMT (Cut, Make, Trim) apparel manufacturing is bringing a noteworthy transformation. Blending technological advancements with skilled labor, this modern production mode has indeed turned into the linchpin around which the fashion industry orbits. The digitization of manual processes, increasing demand for customization, and the current trend towards sustainability are all contributing to the reshaping exercise.

The introduction of advanced machinery in CMT factories has led to the production of clothes with more precision and less wastage in a shorter period, thus escalating productivity and promoting eco-friendly practices. Furthermore, the ability of CMT manufacturers to customize clothes according to individual preferences is enabling brands to cater to consumers’ unique tastes, further reinforcing brand loyalty. By adopting CMT practices, brands are also able to alleviate surplus production and redundant stock, thereby diminishing waste and contributing to the sustainability narrative. These dynamics are together harmonizing the process of production with consumer demand, revolutionizing the framework of the fashion industry.

Future Trends in CMT Clothing Manufacturing

In a time characterized by rapid technological advancements and changing consumer patterns, Cut, Make, Trim (CMT) clothing manufacturers are expected to adapt to several transformative trends. One such trend is the automation of the clothing manufacturing process. The rise of ‘smart’ machines equipped with Artificial Intelligence (AI) is set to revolutionize the industry. These machines, capable of performing multiple operations simultaneously, will streamline workflows, build efficiency, and significantly reduce human error in the production process.

Another area poised for major change is the adoption of sustainable and ethical practices in CMT manufacturing. Given the growing global awareness regarding the environmental impact of fashion, manufacturers are striving to utilize sustainable materials and processes in their operations. Additionally, the trend towards greater transparency means manufacturers are held accountable for their supply chains, pushing them to ensure their operations adhere to ethical labor practices. This shift not only bolsters global sustainability efforts but also aligns with an emerging consumer preference for ethical, sustainable clothing.

FAQs

What is the role of CMT clothing manufacturers?

CMT clothing manufacturers are responsible for the Cut, Make, and Trim process in the apparel production. They receive designs from fashion houses and are responsible for creating the garments accordingly.

Can you explain the process of customizing clothes in garment manufacturing?

The process of customizing clothes in garment manufacturing involves receiving the design and specifications from the client, then cutting the fabric according to the design, sewing it together, and finally adding the finishing touches like buttons, zips, etc.

What does the art of mastery mean in the context of clothing manufacturing companies?

The art of mastery in clothing manufacturing refers to the high level of skill and expertise required to produce high-quality garments. This includes everything from understanding different types of fabrics to mastering intricate sewing techniques.

Why is tailoring significant in the fashion industry?

Tailoring is significant in the fashion industry because it allows for the creation of custom-fit garments. This not only enhances the comfort and fit for the wearer but also allows for a higher degree of personalization and uniqueness in fashion.

How does customization impact apparel manufacturing?

Customization impacts apparel manufacturing by requiring a more detailed and precise production process. It also often requires more skilled labor and can lead to higher customer satisfaction due to the unique, personalized products.

What are the benefits of CMT apparel production?

CMT apparel production allows for a high degree of customization, can reduce costs for fashion houses as they don’t need to maintain their own manufacturing facilities, and enables rapid production turnaround times.

What are the steps involved in CMT clothing production?

The steps involved in CMT clothing production include receiving the design and specifications, cutting the fabric, sewing the pieces together, and adding any finishing touches such as buttons or zips.

What are some of the challenges faced by clothing manufacturing companies?

Some of the challenges faced by clothing manufacturing companies include maintaining high-quality standards, managing production costs, ensuring timely delivery, and staying up-to-date with the latest fashion trends and technologies.

How is CMT apparel manufacturing reshaping the fashion industry?

CMT apparel manufacturing is reshaping the fashion industry by allowing for a higher degree of customization and faster production times. It is also enabling fashion houses to outsource manufacturing, allowing them to focus on design and marketing.

What are the future trends in CMT clothing manufacturing?

Future trends in CMT clothing manufacturing include increased automation, the use of sustainable materials and methods, and a greater focus on customization and personalization to meet the unique needs and preferences of consumers.