Custom Clothing Manufacturers | Pjgarment

🕑 Release Date: Reports from 2021 to 2023

📚 Data Details: The global custom apparel market has been showing positive growth. In 2021, the market size was valued at USD 45,971.5 million and is expected to expand at a CAGR of 6.38% moving forward. Another report estimates the market size to grow by USD 1,790.48 million from 2023 to 2027, with a CAGR of 7.22% during the forecast period. Additionally, the custom clothing market size is projected to reach USD 86,076.11 million by 2031. The custom made clothes market size was USD 51,890 million in 2021 and is projected to touch USD 161,848.9 million by 2032, at a CAGR of 10.9%.

🎯 Data Source:

Custom Clothing Manufacturers | High-Quality Apparel Production

Welcome to PJ Garment, a leader in the custom clothing manufacturing industry with over two decades of dedicated service. Our journey began with a vision to deliver exceptional quality and craftsmanship in every garment we create. With a team of seasoned designers, skilled artisans, and advanced production facilities, we have established ourselves as the go-to manufacturer for brands that value comfort and promote better sleep. At PJ Garment, we understand that each piece of clothing is more than just fabric and thread—it’s a representation of your brand’s identity and values. We are committed to ensuring that every product that leaves our floor exceeds industry standards and aligns perfectly with your unique specifications. Join us in forging a future where quality custom apparel is the norm, not the exception.

Product Catalog

Our Services

Pattern Making:

At the heart of every exceptional garment is a flawless pattern. Our experienced pattern makers work meticulously to translate your design into a blueprint that ensures the perfect fit and style. Utilizing both traditional techniques and modern software, we create patterns that are the foundation for your custom clothing line.

Sampling:

Before we proceed to full-scale production, we craft high-quality samples to bring your vision to life. This crucial step allows for any necessary adjustments and ensures that every detail meets your expectations. Our sampling process is thorough and efficient, providing you with a tangible representation of your garment for evaluation and approval.

Bulk Production:

With state-of-the-art equipment and a skilled workforce, we are equipped to handle bulk orders with precision and speed. Our production line is optimized for delivering large quantities without compromising on the quality of each individual piece. We adhere strictly to your timelines, ensuring that your custom clothing is ready when you need it

Specialized Garment Construction:

Our capabilities extend to specialized garment construction, catering to niche markets and unique apparel requirements. Whether it’s incorporating technical fabrics, intricate embroidery, or sustainable materials, our team is adept at creating specialized clothing that stands out in the marketplace.

Why Choose Us

Sustainable Practices:In an era where sustainability is not just valued but expected, PJ Garment leads the way with eco-friendly manufacturing processes. We are committed to reducing our carbon footprint through the use of organic materials, renewable energy sources, and waste-minimizing techniques. Our dedication to the environment is woven into every fabric and thread, ensuring that your clothing is not only of premium quality but also responsibly made.

Innovative Techniques:Our team at PJ Garment continually embraces innovation, integrating cutting-edge technology and creative methodologies to enhance the manufacturing process. From 3D prototyping to laser-cut precision, we employ the latest advancements to deliver garments that are a step ahead in design and functionality.

Superior Fabric Quality:Quality begins with the raw materials, which is why we source only the finest fabrics for our custom clothing lines. Our stringent quality control measures and partnerships with reputable suppliers ensure that every garment is crafted from superior textiles that offer longevity, comfort, and elegance.

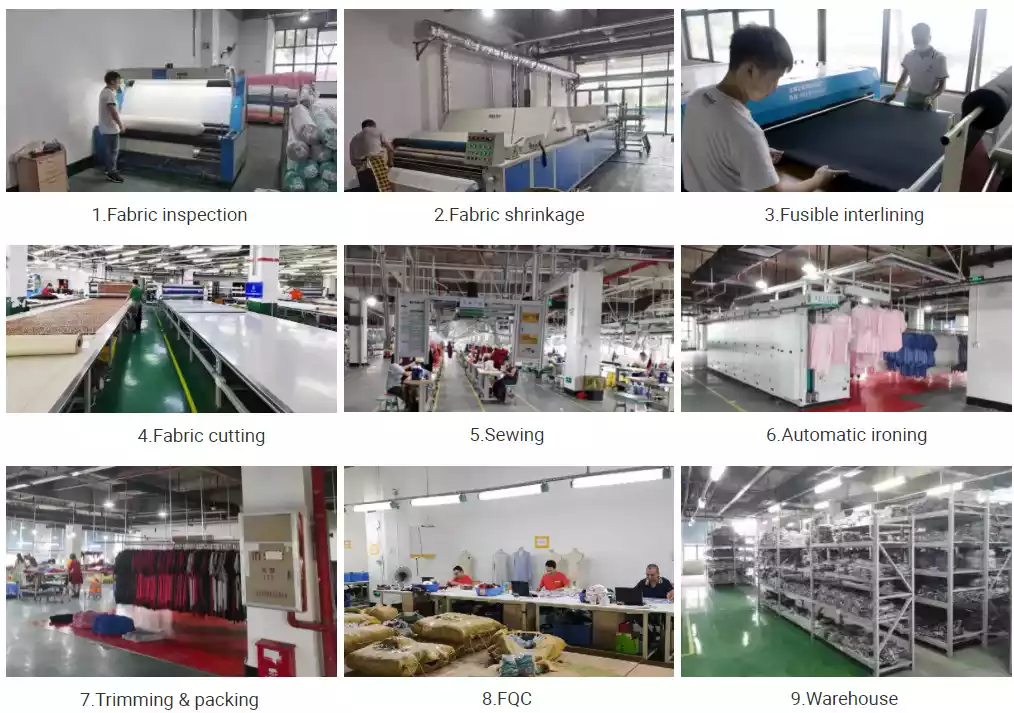

Manufacturing Process

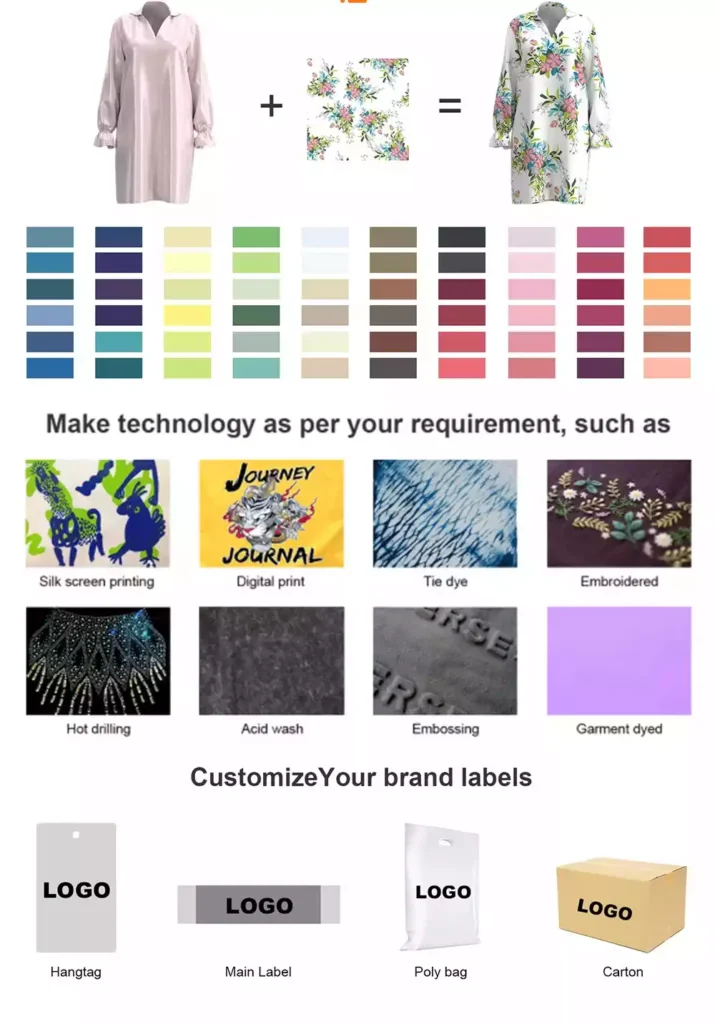

Custsom Service

FAQs

Custom clothing manufacturers offer services such as pattern making, sample development, fabric sourcing, mass production, and quality control. They can help turn your design ideas into a reality.

The time it takes for custom clothing manufacturers to fulfill an order can vary depending on the complexity of the design, the quantity ordered, and their current workload. It is best to discuss timelines with the manufacturer before placing an order.

Yes, many custom clothing manufacturers work with small businesses and startups. They can often accommodate smaller order quantities and provide guidance throughout the production process.

Custom clothing manufacturers can work with a wide range of fabrics, including cotton, bamboo fiber, modal, Sorona, viscose, linen, polyester, silk, satin, and more. They can help you source the right fabric for your design and budget.

To find a reputable custom clothing manufacturer, you can ask for recommendations from other designers, attend trade shows and industry events, search online directories, and read reviews from past clients.

Working with a custom clothing manufacturer can help you bring your unique designs to life, ensure quality control throughout the production process, and streamline the manufacturing process to save time and resources.

Dedicated Customer Support

Our team at Pjgarment Pajama Factory is dedicated to providing exceptional customer support. Whether you have inquiries or need assistance, we are here to address your concerns promptly.

Contact us today to discuss your bespoke clothing requirements. You can contact us via email at [email protected] or fill out the form here.