Cut and Sew Manufacturers in China

Cut and sew manufacturers arose to meet customers’ individual and customized needs, as well as the demand for quality and safety in garments. As the apparel industry has become more competitive and innovative, cut and sew manufacturers have evolved and improved, introducing more advanced technology and equipment, as well as a broader range of services and products.

What are cut and sew manufacturers?

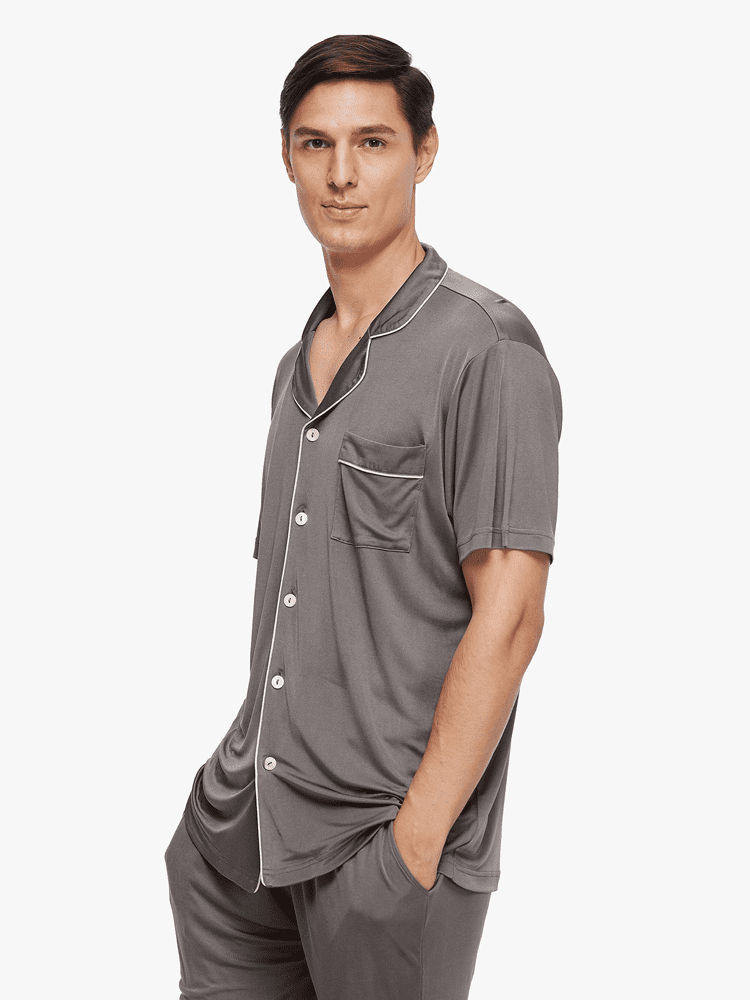

Cut and sew manufacturers are companies that provide custom clothing production services, such as cutting and sewing fabric to the client’s design and specifications. This technique enables the client to design one-of-a-kind and original clothing items, with complete control over the pattern, fabric, color, size, and decoration. Depending on the client’s needs and preferences, cut and sew manufacturers can produce a variety of clothing types such as fashion, pajamas, loungewear,robes, sports, military, medical, and more.

Understanding the Role of Cut and Sew Manufacturers

The Importance of Cut and Sew Manufacturers in the Fashion Industry

Cut and sew manufacturers play a crucial role in the fashion industry. They are responsible for transforming design concepts into tangible garments that meet the highest quality standards. Without the expertise and capabilities of cut and sew manufacturers, it would be nearly impossible for fashion brands to bring their creative visions to life.

- Cut and sew manufacturers ensure that garments are produced with precision and attention to detail, resulting in a finished product that is well-constructed and visually appealing.

- They have the technical knowledge and specialized equipment needed to handle various fabrics and materials, ensuring that the garments are made to withstand regular wear and tear.

- Cut and sew manufacturers also contribute to the overall efficiency of the fashion supply chain by streamlining the production process and reducing lead times.

In order to succeed in the competitive fashion industry, it is essential for brands to collaborate closely with experienced cut and sew manufacturers who understand their unique requirements and can deliver high-quality products on time and within budget.

Key Responsibilities of Cut and Sew Manufacturers

As cut and sew manufacturers, we have several key responsibilities that contribute to the success of the fashion industry. These responsibilities include:

- Pattern making and grading: We are responsible for creating accurate patterns and grading them to ensure consistent sizing across different garments.

- Fabric sourcing and testing: We carefully select and source fabrics that meet the quality standards and specifications of our clients. We also conduct thorough testing to ensure the fabric’s durability and performance.

- Cutting and sewing: Our skilled team of artisans meticulously cut and sew the fabric pieces together, following the provided patterns and instructions.

- Quality control: We have a rigorous quality control process in place to ensure that each garment meets the highest standards of quality and craftsmanship.

By fulfilling these responsibilities, we play a crucial role in bringing fashion designs to life and delivering high-quality garments to our clients.

Qualities to Look for in a Cut and Sew Manufacturer

When selecting a cut and sew manufacturer, there are several key qualities that we, as buyers, should consider. These qualities will ensure a successful partnership and the production of high-quality garments. Here are some important factors to keep in mind:

Experience and Expertise: Look for a manufacturer with a proven track record in the industry. Their experience and expertise will contribute to the overall quality and efficiency of the manufacturing process.

Attention to Detail: A meticulous attention to detail is crucial in the cut and sew manufacturing process. Look for a manufacturer that pays close attention to every stitch, seam, and finishing detail to ensure the garments meet the highest standards.

Flexibility and Adaptability: The fashion industry is constantly evolving, and it’s important to work with a manufacturer that can adapt to changing trends and requirements. Look for a manufacturer that is flexible and open to new ideas and challenges.

Tip: When evaluating potential cut and sew manufacturers, consider requesting samples or visiting their facilities to get a firsthand look at their workmanship and production capabilities.

Communication and Collaboration: Effective communication is essential for a successful partnership with a cut and sew manufacturer. Look for a manufacturer that is responsive, transparent, and proactive in their communication.

Quality Control Measures: A reliable cut and sew manufacturer will have robust quality control measures in place to ensure the garments meet the desired standards. Look for a manufacturer that conducts thorough inspections and tests at various stages of the manufacturing process.

Ethical and Sustainable Practices: As responsible buyers, it’s important to work with manufacturers that prioritize ethical and sustainable practices. Look for a manufacturer that values fair labor practices, uses environmentally friendly materials, and minimizes waste.

By considering these qualities when selecting a cut and sew manufacturer, we can ensure a successful partnership and the production of high-quality garments.

The Pros and Cons of Cut and Sew Manufacturers

Pros:

- Allow the client to have complete creative control over the garment pattern, fabric, color, size, and decoration, creating unique and original clothing products.

- Produce high-quality garments that stand out in the market, as they are different from the mass-produced ones. This can attract more customers and increase the value of the clothing brand.

- Cater to various types of clothing, such as fashion, swimwear, pyjamas or pajamas, robes, and more, depending on the client’s needs and preferences.

Cons:

- Take longer to produce the garments, as they require a more complex and time-consuming process, from designing, sampling, producing, to shipping.

- Cost more than ready-made garments, as they involve more labor, materials, and equipment. This can affect the profit margin and affordability of the clothing brand.

- Not suitable for small quantities, as they usually have a minimum order requirement. This can limit the flexibility and scalability of the clothing brand.

Collaborating with Cut and Sew Manufacturers

Effective Communication with Cut and Sew Manufacturers

When it comes to effective communication with cut and sew manufacturers, it is crucial to establish clear channels of communication and maintain open lines of dialogue throughout the manufacturing process. This ensures that both parties are on the same page and can address any issues or concerns promptly.

To facilitate effective communication, it is important to:

- Provide detailed specifications and instructions in writing, clearly outlining the desired outcome and any specific requirements.

- Schedule regular check-ins and progress updates to stay informed about the manufacturing timeline and address any potential delays.

- Be responsive and available to answer any questions or provide clarification promptly.

Remember, effective communication is the key to a successful collaboration with cut and sew manufacturers, as it helps to minimize misunderstandings and ensures that the final product meets the desired quality standards.

Establishing Clear Expectations and Deadlines

When collaborating with cut and sew manufacturers, it is crucial to establish clear expectations and deadlines. This ensures that both parties are on the same page and can work towards a common goal. Clarity is key when discussing project requirements, timelines, and deliverables. It is important to clearly communicate the desired outcome and any specific details or specifications that are essential for the project’s success.

To effectively establish clear expectations and deadlines, consider the following:

Define project scope: Clearly define the scope of the project, including the specific tasks, materials, and quantities involved. This helps prevent misunderstandings and ensures that everyone is aware of what needs to be done.

Agree on timelines: Set realistic and achievable timelines for each stage of the project. This allows for proper planning and coordination, ensuring that deadlines are met without compromising quality.

Communicate regularly: Maintain open and frequent communication with the cut and sew manufacturer throughout the project. This helps address any issues or concerns promptly and allows for adjustments to be made if necessary.

Document agreements: Keep a record of all agreements, including project specifications, timelines, and any changes or updates. This serves as a reference point and helps avoid any misunderstandings or disputes in the future.

By following these steps, we can establish clear expectations and deadlines with our cut and sew manufacturers, fostering a productive and successful collaboration.

Managing Quality Control in Cut and Sew Manufacturing

Quality control is a critical aspect of cut and sew manufacturing. It ensures that the final products meet the required standards and specifications. Attention to detail is crucial during the quality control process to identify any defects or inconsistencies. Here are some key points to consider when managing quality control:

- Conduct regular inspections at different stages of the manufacturing process to catch any issues early on.

- Implement a thorough sampling plan to test a representative sample of the finished products.

- Use standardized quality control procedures to maintain consistency and reliability.

- Train and educate the production team on quality control techniques and standards.

Tip: Establish clear communication channels with the cut and sew manufacturer to address any quality control concerns promptly.

By prioritizing quality control, we can ensure that our products meet the highest standards and exceed our customers’ expectations.

Cut and Sew Manufacturing Process

1.Fabric Selection

2.Style Selection

3.Pattern Printing Process

4,Processing and Production

5,Shipment

By Courier

By Air

By Ocean

| Transportation Mode | Advantages | Disadvantages | Typical Use Cases |

|---|---|---|---|

| By Courier | - Fast delivery for small parcels. - Door-to-door service. - Tracking and security features. |

- Expensive for larger shipments. - Limited by size and weight constraints. |

- Urgent documents and small packages. - High-value, time-sensitive items. |

| By Air | - Fastest mode for long distances. - Reliable and frequent departures. - Good for perishable goods. |

- More expensive than ocean freight. - Subject to weather and airspace restrictions. |

- Time-sensitive shipments. - Perishables and high-value goods. - Emergency supplies. |

| By Ocean | - Cost-effective for large volumes. - Less carbon footprint than air freight. - Suitable for bulky, heavy items. |

- Slower transit time. - Vulnerable to weather and port delays. |

- Bulk commodities and heavy machinery. - Non-urgent, large shipments. - Cost-sensitive goods. |

FAQs

Cut and sew manufacturers play a crucial role in the fashion industry by producing garments from raw materials. They are responsible for cutting fabric, sewing pieces together, and creating finished products according to the designer’s specifications.

The key responsibilities of cut and sew manufacturers include sourcing materials, pattern making, sample production, fabric cutting, sewing, quality control, and timely delivery of finished products.

When choosing a cut and sew manufacturer, it is important to consider factors such as experience, expertise, production capacity, quality standards, communication skills, and their ability to meet deadlines.

To effectively communicate with cut and sew manufacturers, it is important to establish clear and concise communication channels, provide detailed instructions, ask for regular progress updates, and address any concerns or issues promptly.

To establish clear expectations and deadlines with cut and sew manufacturers, it is crucial to provide detailed production requirements, discuss timelines and delivery dates upfront, and have a written agreement in place to ensure both parties are on the same page.

To manage quality control in cut and sew manufacturing, it is important to conduct regular inspections, implement quality control processes at different stages of production, communicate quality standards clearly, and address any quality issues promptly.

Contact Us

Contact us today to discuss your bespoke clothing requirements. You can contact us via email at [email protected] or fill out the form here.

Premium Clothing Manufacturers Services

If you are looking for professionals in apparel design and custom clothing manufacture, Pjgarment is the best choice for the finest and longest-lasting product quality.