Garment Factory | Pjgarment

🕑 Release Date: Various dates from 2022 to 2024

📚 Data Details: Global garment factory statistics show that China remains the top global clothing exporter with approximately 31.7 percent market share in 2022. The United States and China are the largest markets for apparel demand. As of 2024, there are 298,036 apparel manufacturing businesses globally, with a slight decline of -0.1% from 2023. Australia’s apparel market revenue is projected to reach around 22 billion U.S. dollars by 2027. Industry-wide revenue has been declining at a CAGR of 5.0% over the past five years, expected to reach $718.6 billion in 2023.

🎯 Data Source:

About Us

Product Catalog

At PJGarment, we are proud to offer a comprehensive suite of services designed to meet the diverse needs of our clients.

Here’s a rundown of the specialized services you can expect from our garment factory:

Our OEM services allow you to bring your established designs to life. For example, if you have a specific vision for a line of luxury silk pajamas, our garment factory will meticulously produce these items to your exact specifications, ensuring that your brand’s standards for quality and design are met with precision.

For those looking to tap into our in-house creativity, our ODM services are the perfect fit. Suppose you want to launch a new line of eco-friendly loungewear but need design expertise. Our garment factory’s design team will develop unique items that align with your vision while incorporating the latest trends and sustainable practices.

Our custom design services are all about personalization. Let’s say a boutique hotel wants to offer guests personalized robes as part of their luxury experience. Our garment factory will work closely with you to design custom robes featuring the hotel’s branding, made with the finest materials to ensure guest comfort.

If you’re aiming to expand your brand with your own line of sleepwear, our private labeling service is your go-to solution. For instance, an online retailer looking to add a line of organic cotton nightgowns can rely on our garment factory to produce and label these garments under the retailer’s brand name, ready for sale on their website.

Our garment factory takes pride in a stringent quality assurance system designed to deliver products that are not only exemplary in craftsmanship but also meet international standards.

Here’s how we ensure the quality of every piece that leaves our factory:

Quality Control Processes:

Our quality control procedures are meticulous and multi-tiered. For instance, when we receive a batch of fabric, it undergoes a thorough inspection for defects or inconsistencies in color and texture. During production, each garment is inspected at various stages – post-cutting, during assembly, and after finishing – to identify any issues with stitching, fit, or construction. Before packaging, a final inspection is conducted where a random sample of the finished batch is tested against the client’s specifications and our quality benchmarks.

Certifications and Standards:

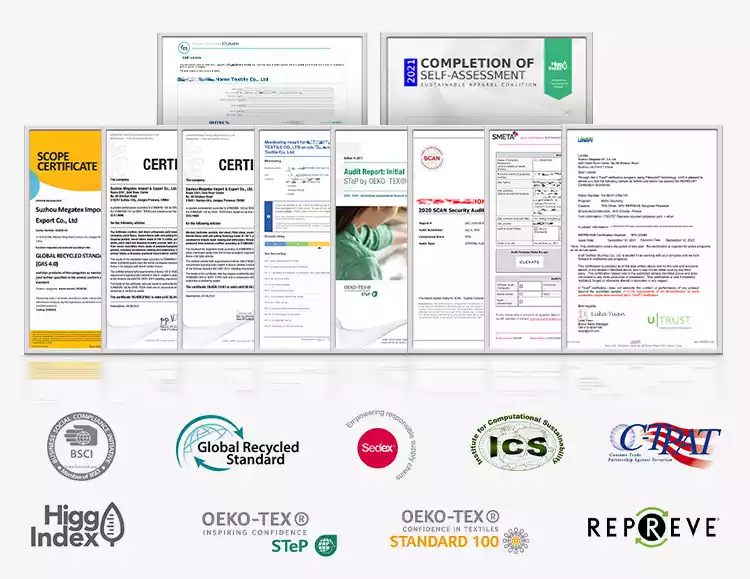

PJGarment adheres to international quality standards such as ISO 9001 for quality management systems. This ensures that our processes are consistently reviewed and improved upon for efficiency and effectiveness. Moreover, our garment factory complies with OEKO-TEX Standard 100, which certifies that our textiles are free from harmful substances, making them safe for consumers and environmentally friendly.

Awards and Recognitions:

Our commitment to quality has not gone unnoticed. As a testament to our efforts, our garment factory was honored with the “Best Quality Pajama Factory” award at the Global Textile Industry Awards last year. This recognition was based on our exceptional product quality, innovation in design, and sustainable production practices.

Sustainability and Ethical Standards:

In addition to quality, we prioritize sustainability and ethics. We have achieved the Global Organic Textile Standard (GOTS) certification, indicating that our organic textiles meet stringent environmental and social criteria along the entire supply chain. Furthermore, our factory is audited regularly to ensure compliance with the BSCI (Business Social Compliance Initiative) to promote fair labor practices and safe working conditions.

Garment Factory Certification

FAQs

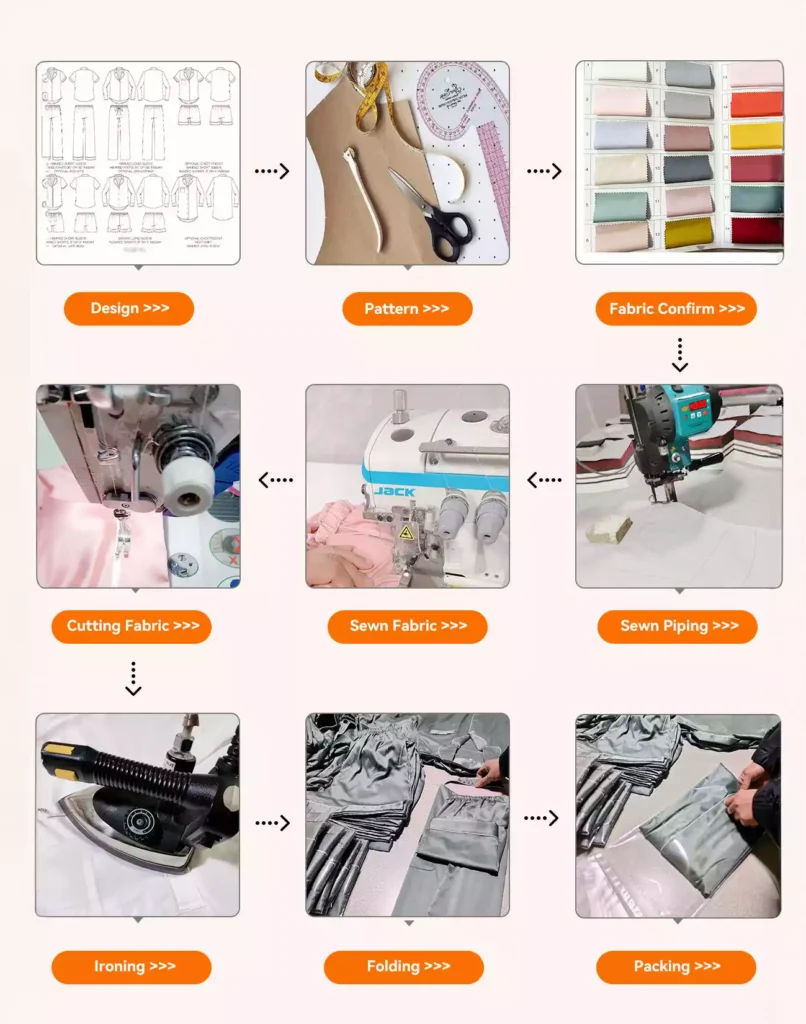

A garment factory typically provides services such as pattern making, sample development, fabric sourcing, garment production, quality control, and packaging.

To find a reliable garment factory, you can conduct thorough research, ask for referrals, visit trade shows, and personally inspect the facilities and production processes.

The production capacity of a garment factory varies, but it can range from a few hundred to several thousand pieces per day, depending on the size and capabilities of the factory.

Common challenges in garment factory production include maintaining quality standards, meeting production deadlines, dealing with fluctuating demand, and ensuring efficient supply chain management.

When choosing a garment factory, it’s important to consider factors such as production capabilities, quality standards, communication proficiency, pricing, and ethical labor practices.

A garment factory can optimize production for cost-effectiveness by implementing efficient production processes, utilizing technology, managing inventory effectively, and minimizing waste and rework.

Dedicated Customer Support

Our team at Pajama Factory is dedicated to providing exceptional customer support. Whether you have inquiries or need assistance, we are here to address your concerns promptly.

Consult with Our Experts for Your Manufacturing Needs. You can contact us via email at [email protected] or fill out the form here.