Women’s Wear Wonders: Embrace Style with a Trusted Manufacturer

In the fashion industry, where trends rapidly evolve and consumer demands shift, the role of a reliable women’s wear manufacturer cannot be overstated. They are the ones who convert the creative visions of fashion designers into tangible garments and play an invaluable role in supplying high-quality, fashionable clothing that meets market standards.

Entrusting production to a reliable women’s wear manufacturer ensures the consistency of product quality, precise execution of design details, and efficient production timelines. From material sourcing to garment production, quality control, and delivery, every step is essential to bring a collection to life. Hence, it becomes imperative for designers and brands to partner with a manufacturer who demonstrates mastery in these areas of expertise.

Exploring the Advantages of White Label Clothing Manufacturers

In the international sphere of fashion, choosing the services of a white label clothing manufacturer can make a significant difference. A professional global women’s wear manufacturer can elevate the brand reputation by ensuring top-quality production and offering a broad range of trendy designs for selection. This allows clothing companies to build their international recognition, as they have a high degree of freedom to create merchandise that embodies their unique brand image and sells well in the global market.

Overlaying the added advantages, these manufacturers also come with well-established supply chains, creating a smooth path from production to the end consumer. The businesses partnering with a global women’s wear manufacturer gain the opportunity to tap into a vast network of fabric suppliers and other necessary resources. Therefore, it not only streamlines the production process but also provides highly desirable cost-effective and time-efficient solutions to stay ahead in the fiercely competitive FXashion industry.

Understanding the Role of B2B Clothing Manufacturers in Fashion

In the world of fashion, business-to-business (B2B) clothing manufacturers play an integral and transformative role. These entities facilitate the translation of a designer’s imagination into tangible clothing items, ready to be showcased on global platforms. In the realm of women’s and girls’ wear manufacturing in Australia, these B2B manufacturers prove to be of paramount importance. Their competencies in production, coupled with their intimate knowledge of fabric and design intricacies, allow Australian labels and designers to compete on the international stage effectively.

B2B clothing manufacturers often act as the invisible but essential backbone of the fashion industry. They comprehensively contribute to industry trends, product assortment, sustainable practices and overall market growth. With respect to women’s and girls’ wear manufacturing in Australia, these manufacturers help maintain the industry’s edge by constantly innovating and improving the manufacturing process. This includes introducing new methods and technologies to improve product quality, streamline production processes and increase overall efficiency – all contributing towards the advancement of the vibrant and dynamic fashion landscape in Australia.

The Power of Collaboration: How Designers and Manufacturers Work Together

In the bustling world of fashion, the synergy formed between designers and women’s clothing manufacturing companies is crucial not only for the success of each separate entity but also for the seamless functioning of the fashion industry as a whole. Designers bring creativity and innovation while manufacturers transform these abstract concepts into tangible garments. While designers may have the ability to dream, it is the manufacturers that house the technical expertise to actualize those dreams, thereby making this collaboration a powerful duo that shapes the outlook of women’s wear.

However, this collaboration is not one-directional but operates on mutual feedback. Women’s clothing manufacturing companies offer insights into areas such as functionality, practicality, and cost-efficiency. They carry detailed knowledge of materials, production processes, and current technologies, which directly influence the feasibility and final outcome of a design. On the other hand, designers keep manufacturers updated on trending aesthetics and consumer preferences, thereby guiding them in their production techniques. Hence, this extraordinary symbiosis between designers and manufacturers drives the evolution of women’s wear, making it a significant aspect of the fashion industry.

Exploring the Process: From Design Concept to Retail Rack

In the domain of women’s wear manufacturing, the journey from a design concept to a product gracing a retail rack is indeed intriguing. The process initiates with an idea stimulated by various influences such as current fashion sensibilities, market studies, and customer preferences. This concept is then simplified into initial sketches, setting down the basis for patterns and sampling. The women’s wear manufacturer plays a crucial role in this stage as they have the expertise to translate these designs into samples that vividly represent the intended end product.

Beyond the design, the women’s wear manufacturer is deeply involved in material sourcing, ensuring not only the quality of fabrics but also their suitability in bringing to life the design in the sketches. consequentially, rigorous prototype iterations and precise adjustments are then undertaken. The next phases involve bulk production, quality checking, and packaging, leading up to the product’s final placement on a retail rack. The sophisticated mix of creativity, technical knowledge, industry insight, and manufacturing expertise becomes palpable in the final product, an embodiment of style and comfort designed for the modern woman.

The process of transforming a design concept into a tangible product on the retail rack involves several key steps:

• The inception of an idea: This is stimulated by various influences such as current fashion trends, market studies, and customer preferences. It serves as the starting point for all subsequent stages in the process.

• Initial sketching: The concept is simplified into initial sketches that lay down the foundation for patterns and sampling.

• Role of women’s wear manufacturer: At this stage, manufacturers play a crucial role as they possess the expertise to translate these designs into samples that vividly represent the intended end product.

• Material sourcing: Beyond designing, manufacturers are deeply involved in material sourcing. They ensure not only the quality but also suitability of fabrics that can bring life to design sketches.

• Prototype iterations and adjustments: Rigorous prototype iterations are undertaken based on feedback received from different stakeholders including designers, marketing teams or focus groups. Precise adjustments are made to perfect each aspect of design before it moves forward to production phase.

• Bulk production and Quality Checking : After finalizing prototypes, bulk production begins followed by stringent quality checking processes which ensures consistency across all products while maintaining high standards set during prototype development phase.

• Packaging : Once checked for quality assurance , products undergo packaging where careful attention is paid towards preserving fabric integrity along with making sure its aesthetic appeal remains intact when reached at retailers’ end .

• Final placement on retail racks : Finally , after passing through aforementioned phases successfully , ready-to-sell clothes make their way onto retail racks awaiting customers who appreciate style blended with comfort designed specifically keeping modern woman’s needs in mind .

In conclusion, bringing a clothing item from conception to reality requires a sophisticated mix of creativity, technical knowledge industry insight,and manufacturing expertise – all factors contributing significantly towards creating garments embodying both style and comfort for today’s discerning women.

Choosing Quality: The Importance of Fabric Selection in Women’s Wear

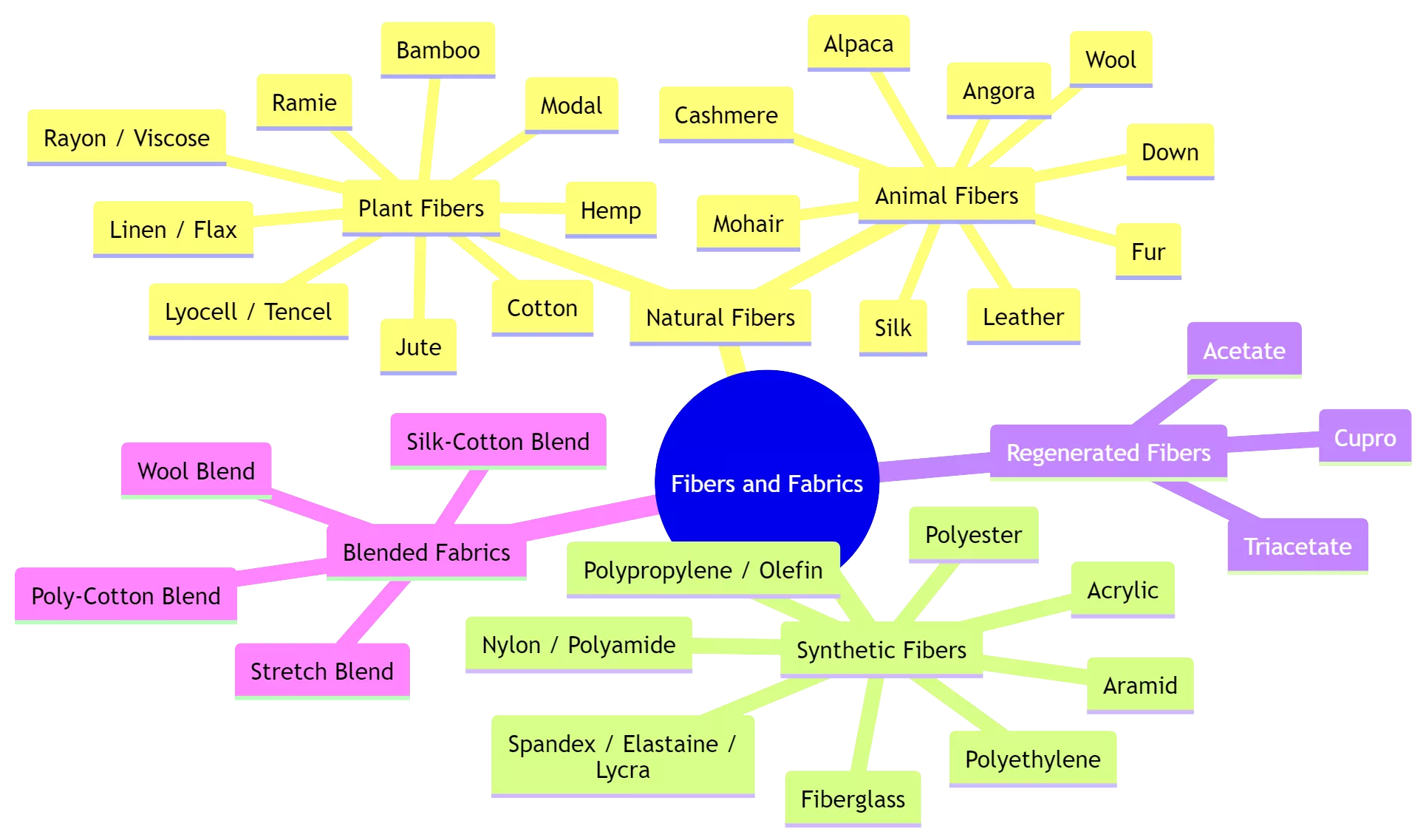

Fabric selection plays a pivotal role in the production process for private label women’s clothing manufacturers. The choice of material significantly affects the comfort, durability, and overall quality of the final product. It is a meticulous task that requires a profound understanding of various fabrics, their characteristics, their interactions with different body types, and how they respond to numerous manufacturing processes.

Despite the rise of synthetic materials and blends, natural fibers continue to be highly sought after in women’s clothing due to their inherent advantages. Cotton and silk, for example, are favored for their breathability and softness, while wool and cashmere are chosen for their warmth. Private label women’s clothing manufacturers are combining the use of these traditional materials with innovative manufacturing techniques, thus achieving the perfect blend of quality, comfort and style in women’s wear. It is clear that the choice of fabric is a critical element in the production process, shaping the way a final garment looks, feels, and performs.

Sustainable Practices: The Rise of Eco-Friendly Women’s Wear Manufacturing

As the fashion industry has grown, so too has its environmental footprint. Yet, in response to this challenge, a growing number of women’s clothing manufacturers have started to prioritize sustainable practices. Leveraging modern innovations and traditional techniques, they are revolutionizing the way we think about fashion. This movement towards eco-friendliness is not merely a trend but an industry-wide shift to responsible manufacturing.

This new wave of sustainability entails using recycled or organic materials, minimizing waste, reducing energy usage, and respecting human rights. Not only are these practices environmentally beneficial, but they also resonate profoundly with conscious consumers, increasing brand reputation. Through this dedicated focus on sustainability, women’s clothing manufacturers are creating a double benefit: producing appealing, high-quality garments while also helping to preserve our planet for future generations.

The Impact of Technology on Modern Clothing Manufacturing

With continuous evolution and advancement in technology, b2b clothing manufacturers have embraced innovations that streamline their processes. Garment production, once a lengthy and craft-intensive process, has been radically transformed by technologies such as 3D printing, augmented reality, and artificial intelligence. The use of these cutting-edge technologies has revolutionized the way b2b clothing manufacturers operate, allowing them to produce high quality women’s wear at an unprecedented speed, optimizing efficiency and productivity in the manufacturing process.

Moreover, technology has played a significant role in improving communication between designers, manufacturers, and retailers, fostering greater collaboration and coordination. Advanced software systems enable real-time tracking and automation of various manufacturing processes, thereby reducing errors and inefficiencies. The use of technology in material sourcing, pattern making, and quality control has also seen significant improvements, ensuring superior quality final products and establishing a robust, technologically advanced manufacturing ecosystem. Through the effective integration of technology, b2b clothing manufacturers stand at the forefront of cutting-edge fashion production.

Behind the Scenes: How a Manufacturer Influences the Final Product

In the intricate ecosystem of the fashion industry, white label clothing manufacturers play a pivotal role in shaping the final product. They are the unseen creative force that moulds a conceptual design into a tangible offering, enhancing the original sketch into a product that mirrors market demands and customer expectations. These manufacturers have mastered the art of precision and quality, which is identifiable in the stitching, the choice of fabric, the cut, and even the smallest detail like the buttons or zippers. They are the silent partners behind the immaculate finish and the durable construction of a clothing item.

White label clothing manufacturers are champions of adaptation, continually evolving their techniques and methodologies to meet designer expectations, seasonal trends, and consumer preferences. They intuitively understand the balance between aesthetics and utility, which significantly influences the final product’s design, form, and function. Moreover, their familiarity with various fabric types, cuts, and style forms the backbone of any fashion label, contributing to both its identity and reputation in an overwhelmingly competitive marketplace. Their influence is indeed far-reaching, shaping not just clothing, but also the trends and norms within the world of fashion.

Future of Fashion: Trends and Predictions for Women’s Wear Manufacturing

In the dynamic realm of women’s wear manufacturing, technology and sustainability prove to be the driving forces shaping the future. Current trends lean predominantly towards eco-friendly production while integrating advancements in technology for efficiency and precision. As a leader in the industry, Pjgarment.com continuously evolves to prioritize these trends, ensuring an innovative and conscientious approach to the manufacturing process.

Predictions for the future of fashion heavily lean on the incorporation of augmented and virtual reality, fueling an immersive experience in fashion design and retail. Further, as consumers become increasingly eco-conscious, a shift towards sustainable fabrics and ethical manufacturing practices is imminent. With the consumer at the heart of its operations, Pjgarment.com stands ready to adapt to these anticipations, shaping the future of women’s wear manufacturing. Such projections transform the fashion industry into an arena for responsible creativity, an endeavor in which Pjgarment.com ardently participates.

FAQs

What is the significance of a reliable women’s wear manufacturer?

A reliable women’s wear manufacturer ensures the production of high-quality garments that meet the design specifications and industry standards. They play a key role in fulfilling customer expectations, maintaining brand reputation, and ultimately driving business growth.

What are the benefits of partnering with white label clothing manufacturers?

White label clothing manufacturers allow businesses to sell products under their own brand name, without having to invest heavily in production facilities. They provide flexibility in design customization, help in speeding up the product launch process, and offer cost-effective solutions.

How do B2B clothing manufacturers contribute to the fashion industry?

B2B clothing manufacturers provide integral services to fashion businesses by producing large quantities of garments based on the designer’s vision. They help brands maintain consistency in quality, manage inventory effectively, and meet market demands promptly.

How do designers and manufacturers collaborate in the fashion industry?

Designers and manufacturers work together from the concept stage to the final production. Designers communicate their vision and requirements, while manufacturers suggest technical possibilities and limitations. This collaboration ensures the final product aligns with the intended design while adhering to manufacturing feasibilities.

What is the process of clothing manufacturing, from design concept to retail rack?

The process starts with a design concept, which is then turned into a prototype. This is followed by fabric selection, pattern making, cutting, sewing, finishing, quality checking, packaging, and finally distribution to the retail rack.

Why is fabric selection important in women’s wear?

Fabric selection impacts the comfort, durability, and overall look of the garment. It’s also crucial in conveying a brand’s quality and style. Thus, choosing the right fabric is a significant factor in women’s wear manufacturing.

How is the women’s wear manufacturing industry embracing sustainable practices?

The industry is increasingly adopting eco-friendly practices, such as using organic materials, reducing waste, and minimizing energy consumption. Many manufacturers are also opting for ethical labor practices and transparent supply chains.

How is technology impacting modern clothing manufacturing?

Technology is revolutionizing clothing manufacturing with advancements like automation, 3D printing, and AI. It is enhancing precision, speed, and flexibility in production while also enabling sustainable practices.

How does a manufacturer influence the final product in women’s wear?

A manufacturer has a significant influence on the final product’s quality, fit, and finish. Their expertise in fabric selection, cutting, sewing, and finishing can significantly impact the garment’s overall look and feel.

What are some trends and predictions for the future of women’s wear manufacturing?

Trends in women’s wear manufacturing include a greater emphasis on sustainability, personalized clothing, and digital fashion. Predictions for the future include increased use of technologies like AI and VR in design and manufacturing processes, and a stronger focus on ethical and inclusive practices.