In the development chain of high-end pajamas and loungewear, fabric patterns are a core medium for defining garment texture and conveying brand tone. They not only determine the consumer’s first visual impression but also directly impact the product’s market pricing ability. Designers need to repeatedly refine the visual narrative logic of pattern types and textile patterns during the concept stage (such as the line tension of light luxury florals and the proportional balance of minimalist geometry). Brand owners must assess whether popular fabric patterns align with the season’s market trends and the aesthetic preferences of high-net-worth customers (such as whether the “low-saturation natural textures” for Fall/Winter 2026 suit the target users’ lifestyle). On the factory side, in the sampling and dyeing stages, they often face the most challenging technical bottlenecks: precision in color difference control, the garment suitability of repeat sizes, and the differences in wash durability between digital printing and traditional techniques.

As an OEM/ODM factory that has long served international high-end brands such as SKIMS, Hanro, Cozy Earth, and Aubade, PJGarment is acutely aware of the “interface gap” from design sketches to mass production: how to verify the feasibility of fabric patterns during the sample phase? When to choose digital printing over transfer printing to balance texture and cost? How to convert the popularity of market trends into executable pattern designs in the context of high-end pajamas?

This article will focus on high-end pajamas as a vertical scene, deeply decoding the key details of sampling and dyeing processes (such as optimizing color fastness for reactive printing and controlling pattern precision in digital direct printing). It will also analyze the popular trends of fabric patterns for 2026-2027 (such as “therapeutic textures” and “vintage plush jacquard”), providing brands and designers with a full-chain strategy from pattern selection to process implementation. This aims to help rapidly control high-end texture, shorten sampling lead time, reduce rework losses, and mitigate market testing risk.

What are fabric patterns: the core link connecting design and craftsmanship.

Fabric patterns refer to the pattern and texture system presented on the surface of textiles, encompassing both flat patterns achieved through visual design techniques such as printing and dyeing (e.g., stripes, checks, florals) and three-dimensional patterns created by weaving structures (e.g., jacquard, herringbone).

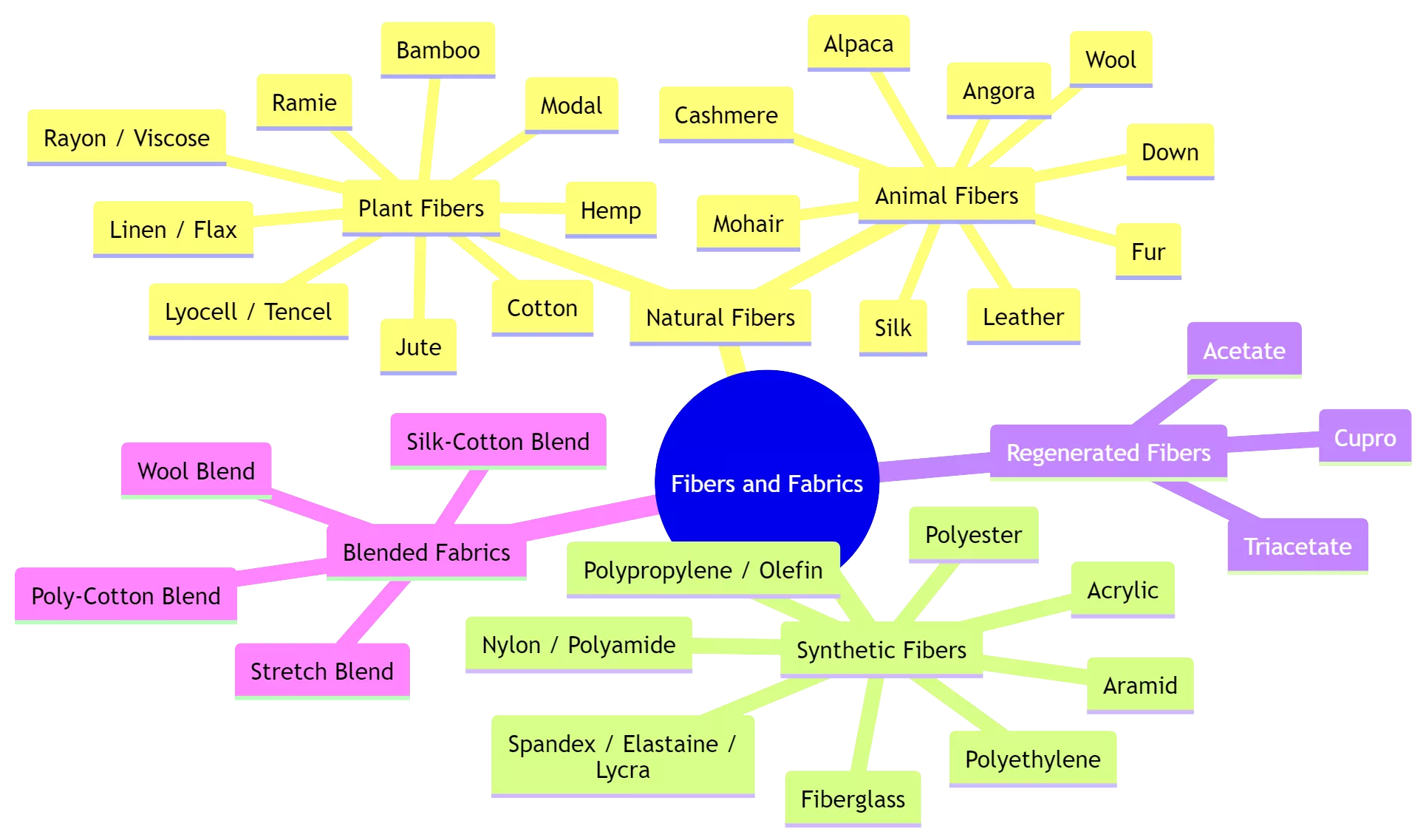

It is closely related to concepts such as textile patterns, fabric design patterns, and cloth patterns, each with its own emphasis:

- Textile patterns focus on the overall design vocabulary in the textile field, covering the entire design expression from fiber selection to finished product presentation.

- Fabric patterns concentrate on the specific patterns at the fabric level, serving as the direct medium through which design intentions are transformed into tangible fabrics.

- Pattern types are used for systematic classification and standardized naming of various patterns (e.g., geometric patterns and botanical patterns belong to different pattern types).

- Cloth patterns are more inclined towards the intuitive pattern description of finished fabrics, overlapping considerably with fabric patterns but with a narrower scope.

For high-end pajamas and loungewear, the value of fabric patterns far exceeds mere aesthetic appeal: it directly affects wearing comfort (e.g., delicate textures reduce skin friction), post-wash stability (e.g., color fastness and deformation control of complex patterns), and the accuracy of pattern alignment during the sewing process (one of the core considerations in patterns in clothing, such as the alignment requirements of stripes on pajama collars and plackets).

Therefore, in the production chain of high-end pajamas, every link from final design approval to small batch trial production—design concept output, fabric sampling confirmation, dyeing process selection, finishing treatment, and trial production verification—requires the formulation of tailored processes and material choices for specific fabric patterns, ensuring that the final product accurately reflects the design intent while meeting the dual demands of comfort and durability for high-end consumers.

Sampling: A crucial control valve for the precision implementation of fabric patterns in high-end pajamas.

The core purpose and types of sampling (adapted for high-end pajamas scenario):

Sampling is a key verification step in converting design intent into physical fabric. For the material characteristics of high-end pajamas (such as 22 or 30 Momme Silk, Lenzing Modal, Cupro, Lyocell and wool blended fabric, mulberry silk and acetate blended fabric, cotton lyocell linen mulberry silk blended fabric, TENCEL™ and acetate blended fabric, and jacquard cotton), we categorize sampling into three core types:

- Strike-off/lab dip: Not only confirms the color swatch and color saturation but also validates the dye’s color consistency on high-end fabrics (such as the transparency of acid dyes on mulberry silk), serving as a benchmark for subsequent printing and dyeing.

- Digital sample: Short-run quick samples, suitable for testing various fabric patterns on the target fabric’s visual effects (such as the minimalist stripes of SKIMS vs. the exquisite florals of Hanro), helping brands quickly identify trend directions.

- Proto/fit sample: The focus during the sample stage is to confirm the visual coordination of pattern pieces and pattern repeat (such as whether the large-scale floral repeat of a high-end robe appears bulky) and the feasibility of sewing alignment.

For brands, early strike-offs and digital samples can expose issues in advance (such as color bleeding of floral patterns on silk), preventing cost losses caused by bulk printing and dyeing.

Our sampling process (exclusive practices for high-end pajamas).

Based on our experience serving international high-end brands, we have established a closed-loop process tailored for the pajamas scene:

1.Design draft acceptance: Strictly confirm the artwork resolution (≥300 DPI), color codes (Pantone fashion or CMYK values), and repeat size (must match the pattern piece sizes, such as the leg opening alignment for sleep pants).

2.Lab dip calibration: Select specialized dyes for high-end fabric characteristics (e.g., acid dyes for silk), and lock in the main color through standard color cards and ICC color matching processes to ensure consistency across batches.

3.Sample printing selection:

- Fine floral/geometric patterns: Use digital printing (with a resolution of up to 1440 DPI) to restore details;

- Large areas of solid color with texture: Use screen printing (suitable for the durability requirements of high-end cotton);

- Special metallic sheen patterns: Use transfer printing (suitable for the light luxury feel of the Aubade style).

4.Sample fitting validation: Inspect pattern direction (e.g., vertical flow of striped nightgowns), matching alignment (e.g., Symmetrical check pattern on the front and back panels and placket checks alignment), and fabric utilization rate (high-end fabric loss must be controlled to ≤10%).

5.Stringent washing tests: Simulate the care habits of high-end clientele (e.g., gentle hand washing/machine washing of silk), repeat 3 cycles of washing + rubbing + sweat stain tests, to verify the durability and color fastness of fabric patterns (must meet ISO 105 standard level 3 or above).

Common sampling problems and exclusive solutions for high-end nightwear.

1.Color difference exceeds expectations:

- Strategy: Share standardized ICC profiles with upstream and downstream partners, increase lab dip iterations by 2 times for sensitive fabrics like silk, and adjust dye pH values to match fabric characteristics.

2.Stretch and distortion of knitted fabric patterns:

- Strategy: Pre-shrink modal/silk knitted fabrics before sampling, incorporate pattern morph elastic compensation algorithms, and calibrate piece stretch rates with the pattern making team during the marker making stage.

3.High difficulty repeat alignment (matching pattern):

- Strategy: Recommend that the initial design specify pattern repeat orientation (e.g., horizontal priority), set allowable repeat tolerance ≤2mm, and use laser alignment equipment to enhance sewing accuracy (e.g., pattern matching at seams for the left and right panels of striped robes).

Dyeing and printing process selection: Customize the optimal production route for high-end pajama fabric patterns.

The final presentation of fabric patterns depends 90% on the precise selection of dyeing and printing processes. Below is a breakdown of the adaptation logic and practical key points of the four core processes for high-end pajamas, helping brands secure an efficient and high-quality production route during the sample making stage.

1.Digital Printing: The preferred solution for high-detail patterns.

Core Advantages:

- Color reproduction accuracy reaches △E≤1.5 (international high-end standard), perfectly suited for complex or photographic-grade fabric patterns (such as EBERJEY’ gradient textures and PRINTFRESH’s ultra-fine florals);

- Short-run costs are 30% lower than traditional processes, supporting the rapid launch of small batch sleepwear capsules (such as seasonal limited editions);

- No need for screen making, sample making cycle compressed to within 24 hours.

Limitations and Solutions:

- Ink spots easily penetrate natural fibers (mulberry silk/cotton): for mulberry silk, a nano-level pre-treatment coating is applied to enhance ink adhesion.

- Colorfastness needs to be enhanced: post-printing, an additional low-temperature fixation finishing is applied to ensure wash fastness reaches ISO 105 X12 standard Grade 3 or above.

Applicable Scenarios:

- Limited edition high-end pajamas (such as Aubade’s artistic collaboration series);

- High-detail textile patterns (such as photo-realistic botanical prints, 3D geometric patterns);

- Multi-colored fabric design patterns.

Key points for practical sample making:

- Provide layered artwork at ≥300dpi (Adobe Illustrator format preferred); If Adobe Illustrator format print patterns are not available, PDF or PSD formats can be used. If none of these are available, high-resolution PNG or JPG files with a resolution of at least 4000*4000 pixels are acceptable.

- Specify brand-exclusive ICC profile (e.g., Pantone Textile Color Card); Pantone color cards for fabric color matching typically use .TCX and .TPG . TCX (Textile Cotton Extended): Substrate is cotton fabric with texture consistent with textile materials, providing color representation that closely matches actual fabric dyeing effects. It is the mainstream choice for precise color matching in the textile industry. TPG (Textile Paper Green): Substrate is eco-friendly paper (replacing the original TPX paper-based cards), featuring a smooth and lightweight texture. It is suitable for initial color selection or quick reference for non-cotton substrates, though color presentation may exhibit subtle differences from TCX on cotton substrates. Label Suffix: TCX color codes end with “TCX”; TPG ends with “TPG”.

- Test the impact of different pre-treatment methods on the hand feel of silk/cotton fabrics (to avoid stiffness).

2.Sublimation/Transfer Printing: An Efficient Choice for Functional Loungewear

Core Advantages:

- Bright and highly penetrative, suitable for large-area repeat fabric patterns (such as lululemon-like geometric patterns for active loungewear);

- Polyester substrate with a wash fastness of grade 5 and excellent abrasion resistance.

Limitations and Solutions:

- Only suitable for fabrics with a polyester content ≥70% (poor compatibility with natural fibers);

- The heat pressing process tends to cause fabric shrinkage (pre-shrinking treatment is required).

Applicable Scenarios:

- Polyester blend functional loungewear (such as quick-dry loungewear, antibacterial series);

- Cloth patterns for outdoor loungewear (such as camouflage, geometric patchwork).

Key points for practical sample making:

- Control the heat pressing temperature at 180-200℃ (adjusted according to fabric thickness);

- Test dry/wet rub fastness (abrasion colorfastness);

- Add elasticity recovery testing for knit fabrics to prevent pattern deformation.

3.Traditional Screen Printing: The optimal bulk solution for classic patterns.

Core Advantages:

- High color saturation (especially fluorescent/metallic colors), suitable for mass production (cost-optimal for single style ≥500 pieces);

- Thick ink layer effects are unique (such as flocked stripes and embossed checks), enhancing a premium texture.

Limitations:

- Costs increase linearly with multiple colors (≥6 colors);

- Fine details (such as patterns ≤2mm) tend to blur.

Applicable Scenarios:

- Classic fabric patterns (such as La Perla’s basic stripes and Burberry-style checks);

- Retro popular fabric patterns (such as 1970s polka dots and workwear plaid).

Key points for practical sample making:

- Color separation uses spot color channels (to avoid CMYK color mixing deviation);

- Screen selection: 120 mesh suitable for thick ink layers (such as flocking texture), 150 mesh suitable for delicate patterns;

- Thick ink layers require additional soft hand finish treatment (to avoid stiff touch).

4.Jacquard and woven textures: three-dimensional expression of high-end quality

Core difference:

- Jacquard: complex patterns (such as Frette’s silk robe dragon pattern) realized by electronic jacquard machines, with warp and weft yarns interwoven to form three-dimensional textures;

- Dobby weave: suitable for simple geometric patterns (such as herringbone and small checks), with costs approximately 20% lower than Jacquard.

Core Advantages:

- No surface printing or dyeing layer, offering a more skin-friendly touch (suitable for high-end pajamas for sensitive skin);

- Strong three-dimensional effect, increasing product premium potential (selling price over 50% higher than printed styles).

Applicable Scenarios:

- High-end jacquard bathrobes (such as silk/velvet materials);

- Autumn and winter brushed jacquard loungewear (such as cashmere blend dobby plaid).

Key points for production practice:

- The fabric structure design must match the loom parameters (e.g., silk jacquard with warp density ≥120 ends per inch);

- Balance pattern complexity with fabric softness (avoid overly dense jacquard causing stiffness);

- Test post-wash dimensional stability during sample making (jacquard fabrics tend to shrink and require preshrinking treatment).

Remark:Jacquard weaving is not only suitable for woven fabrics but can also be used for knitted fabrics, as shown in the image below.

5.Finishing: the final mile of pattern texture

Finishing directly determines the final tactile feel and visual impact of fabric patterns:

- Soft finishing: for digital printed silk pajamas, use organic silicone softener to ensure a bare-skin-like touch;

- Vintage effect: add enzyme wash to popular fabric patterns (such as vintage floral) to create a worn layering effect;

- Wrinkle resistance treatment: apply nano wrinkle-resistant coating to cotton-linen pajamas to reduce ironing needs.

- Brushing / Raising: autumn-winter stripes pajamas are carbon brushed to enhance warmth and texture.

Practical case:

When designing jacquard patterns for Pelle Vavare’s cotton robes, we added low-temperature steam setting and anti-pilling finishing to ensure both pattern dimensionality and durability.

Market Trends: Grasp popular fabric patterns to empower the development of high-end pajama styles.

Trend Signals: Insights from data to high-end brand practices

We monitor the popularity trends of fabric patterns through three core channels:

- Authoritative trend reports: WGSN 2024-2025 loungewear trends, Pinterest annual popular pattern rankings;

- High-end brand updates: quarterly design directions of cooperative clients such as SKIMS, Eberjey, Hanro, Peter Alexander, Calida, Marjolaine, and Aubade Paris;

- Retail data feedback: analysis of top 10 patterns in pajama categories from high-end department stores in North America and Europe, such as Nordstrom and Harrods.

Based on the above insights, four core trends have emerged in popular fabric patterns in the high-end pajamas sector in recent years:

Trend 1: The dual parallel of minimalism and vintage small florals

- Minimalist style: monochrome stripes (fine stripes) and subtle geometric patterns have become the fall-winter staples for brands like SKIMS and Cozy Earth — 0.4cm fine stripes on cotton and bamboo viscose fabric, which are both slimming and high-end.

- Vintage small florals: vintage small floral prints (diameter ≤ 2cm) are making a seasonal comeback. Hanro’s 2026 spring-summer collection uses cotton pointelle fabric paired with light pink daisies, emphasizing a “light French lazy vibe,” with sales increasing by 45% year-on-year.

Trend 2: Sustainable textures, a new rigid demand among high-end customers

Popular fabric patterns are beginning to evolve along a dual track of “eco-friendly + texture.”

- Using recycled yarns (recycled polyester) combined with low-impact dyeing (low water consumption dyeing) to present natural-looking fabric patterns (such as mottled textures resembling botanical dyeing);

- Peter Alexander’s loungewear line uses recycled polyester pajamas with plant-dyeing techniques to create earth-tone striped patterns; despite a 30% price increase, demand still exceeds supply.

Trend 3: Large-scale flat prints, driven by growth through social media sharing

Larger scale florals (diameter ≥15cm) and bold graphic patterns (abstract art motifs) have become the core of “internet celebrity styles” — these patterns deliver strong visual impact in social media posts. La DoubleJ’s printed two-piece set saw a 60% sales increase driven solely by Instagram influencer posts.

Trend 4: Functional patterns, combining aesthetics with practicality

The demand for “invisible functions” among high-end customers is rising:

- Antibacterial pattern: Using silver ion printing technology on cotton fabric to achieve anti-static, radiation protection, deodorizing, and antibacterial effects (used in high-end maternity wear or underwear);

- Night-visible pattern: Adding micro-reflective logos on recycled polyester loungewear, suitable for night owl users’ nighttime needs;

- Quick-dry pattern: Polyester blend fabric combined with hydrophobic printing, targeting sports and loungewear scenarios.

From Trend to Implementation: A Three-Step Practical Approach

1.Build a Trend Matching Matrix

Precisely match candidate popular fabric patterns with commonly used high-end sleepwear materials:

| Pattern Type | Suitable Materials | Core Advantages |

|---|---|---|

| Large-scale floral | silk satin fabric, cotton sateen | Strong luster, highlighting high-end texture |

| Minimalist stripes | bamboo viscose, modal fabric, Cupro fabric | Good drape, fitting the body curve |

| Vintage small floral | cotton jersey fabric, linen fabric | Breathable and skin-friendly, suitable for spring and summer styles |

| Functional antibacterial pattern | hemp fabric, linen fabric, polyester blend | High durability, meeting segmented needs |

2.Sample Making Priority Strategy

- Screen 3-5 potential patterns: prioritize those with high “trend popularity + fabric compatibility” (e.g., silk satin large florals, bamboo viscose minimalist stripes);

- Quick verification: deliver digital samples within 48 hours (to test visual effect), lab dips within 72 hours (to confirm colorfastness), and complete fitting samples within 10 days;

- Small-scale testing: produce 200 pieces of small batch trial sales for the core customer group, and adjust pattern details based on feedback.

3.The art of balancing cost and selling price

- Large-width patterns: fabric waste rate is about 25% (8% for regular styles), requiring a 30% price increase to cover costs;

- Sustainable patterns: low-impact dyeing increases costs by 20%, but product premium can be raised through “eco-friendly labels” (e.g., Hanro’s recycled fiber printed styles have a 50% premium);

- Functional patterns: silver ion printing increases costs by 17%, but repurchase rate rises by 30% (resulting in stronger customer loyalty).

Core to trend implementation — prioritizing manufacturability

Fashion trends are volatile, but the key to success for high-end sleepwear lies in balancing “trend aesthetics + process feasibility.” Therefore, we recommend that brands collaborate with factories at the early stage of trends:

- Confirm in advance whether the pattern’s repeat size fits the pattern pieces (such as the placket alignment requirements for pajamas);

- Test the pattern’s post-wash stability on the target fabric (such as colorfastness of prints on mulberry silk);

- Finalize the core production process (e.g., digital printing vs. screen printing) to ensure rapid mass production.

Only in this way can popular fabric patterns truly be transformed into bestsellers, rather than remaining “theoretical” design concepts.

Tips:Digital printing is suitable for orders under 500 pieces because it requires no plate making, has low startup costs, fast production, and high flexibility; although the unit cost is higher, it becomes economical when spread over small batches. Screen printing is suitable for orders over 500 pieces because the plate-making cost is fixed, the unit cost decreases sharply with increased quantity, efficiency is high, durability is strong, and colors are uniform, making it ideal for large-scale production to optimize costs.

How PJGarment transforms high-end pajamas designs into scalable fabric patterns for mass production

A. High-detail floral implemented in TENCEL™ modal pajamas for spring and summer collections (targeting Eberjey style)

Core challenges:

The designer requires a richly layered small floral pattern on soft TENCEL™ Modal fabric, but the strong ink absorption of modal fibers easily causes color bleeding, and the pattern tends to distort at elastic seams (commonly used elastic waist design in spring and summer modal pajamas).

Practical breakdown (by process steps):

- Process selection: Prioritize digital printing to suit the delicate texture of high-detail floral patterns;

- Pre-treatment optimization: Apply nano-scale pre-treatment coating (customized for modal fibers) to balance ink penetration and hand feel (avoid stiffness);

- Colorfastness locking: Confirm lab dips 3 times (compared with Pantone TCX color card), finally selecting acid dyes combined with low-temperature fixation process;

- Deformation compensation: Apply pattern-morph elastic compensation in the elastic seam area (15% stretch allowance) to ensure pattern alignment after washing.

Result verification:

- Colorfastness reaches ISO 105 standard level 4 (well above the industry requirement of level 3);

- Fabric utilization rate optimized from 12% to 18% (reducing large pattern matching waste);

- The pajama sample passed quality inspection and became a best-seller for their 2025 Spring/Summer collection (accounting for 30% of the series’ sales).

B,Jacquard weaving applied in terry robes for the Autumn/Winter collection (benchmarking against Pellevavare texture).

Core challenges:

The client requires the Autumn/Winter terry robe to maintain the three-dimensional effect of the jacquard weave, while keeping the overall weight under 500g to prevent a heavy feeling when worn.

Practical breakdown (divided by fabric and craftsmanship):

- Structure reconstruction: Adjust the warp density on the loom from 120 ends per inch to 100 ends per inch (maintaining jacquard clarity), using half-jacquard technique to reduce yarn consumption;

- Yarn optimization: Replace 20% of high-count yarn with low-elasticity high-sheen polyester blend yarn to reduce weight and enhance luster;

- Finishing: Localized brushing on raised jacquard areas plus silicone-based softening finish to ensure a soft and smooth hand feel.

Result verification:

- Garment weight 480g (meeting customer requirements), texture comparable to Pellevavare’s similar products;

- Unit cost reduced by 15% (yarn optimization + process simplification)

- Suitable for seasonal launch (production lead time shortened by 10 days), becoming the client’s key item for Fall/Winter 2025.

C,Sustainable limited edition series with recycled yarn + digital printing (benchmarking SKIMS eco-friendly line)

Core challenges:

The client intends to launch a 300-piece small batch limited edition using recycled polyester fiber + digital printing, while meeting GOTS/OEKO-TEX certification standards and controlling the delivery time within 4 weeks.

Practical breakdown (divided into sustainability and efficiency):

- Material selection: Using 100% recycled PET yarn, certified by GOTS;

- Printing process: Utilizing low-energy digital printing equipment (reducing energy consumption by 30%), combined with OEKO-TEX Standard 100 eco-friendly dyes;

- Wastewater optimization: Adjusted printing parameters (ink volume reduced by 10%), resulting in a 25% decrease in wastewater discharge, meeting the brand’s ESG requirements.

- Fast delivery: digital samples ready within 48 hours, small-batch production completed in 10 days.

Result verification:

- The lead time is 22 days (meeting the customer’s 4-week requirement), the cost is 20% higher than the regular style, but the premium is 45% (supported by the eco-friendly label);

- Distinctive selling points are significant: packaging marked with “100% recycled fiber + zero wastewater printing,” increasing repurchase rate by 32%;

- Become the core content of the brand’s 2025 eco-friendly marketing theme, with social media exposure exceeding 700,000 times.

Many designers believe that digital printing has poor color fastness and is prone to severe fading, but this is not the case. For instance, Pjgarment’s digital printing designs, particularly those mimicking denim effects (as shown in the image below), achieve an appearance nearly identical to woven genuine denim fabric. They even replicate the authentic washed denim look with high realism. Moreover, this high-fidelity denim-like printing is significantly more cost-effective than traditional denim printing, with production lead times reduced to just 3 days. After multiple washing machine tests, no color fading was observed. It is evident that the effect of digital printing is related to the printing technology of the factory and the dyes used.

Ten Practical Suggestions for High-End pajama Designers & Brand Owners

[Pre-Design: Precisely Define Pattern Parameters]

1.Clarify the Core Parameters of the Pattern: The design draft should indicate the repeat size (recommended for high-end pajamas ≥ 5 cm to avoid seam breaks), direction (for example, the floral pattern on silk robes should be arranged vertically to fit the body’s curves), and include “placement restrictions” (such as avoiding complex patterns at the elastic waist). If providing printed patterns to the factory, it is recommended to use vector files (Adobe Illustrator). If vector files are not available, a PDF file or PSD file can also be used. If the pattern is a non-placement partial print, a seamless print pattern should be provided to save time.

2.Pre-adapt Fabric to Pattern: When selecting the base fabric, first identify commonly used materials for high-end pajamas (such as knitted TENCEL™ modal, bamboo viscose, organic cotton and woven mulberry silk, linen, hemp ), and then match fabric patterns (flowers and plants, geometric and abstract patterns, classic plaids or stripes, cartoon animals, holiday themes, solid color gradients or subtle watermark patterns).

[Sample making stage: scientific verification of quality]

3.High-detail patterns prioritize digital samples: for high-end pajamas, it is recommended to use 600 DPI digital samples to verify details (such as petal edge clarity), saving 50% time compared to traditional sampling. If you are unsure about the clarity of the high-detail pattern, please provide vector files (Adobe Illustrator) or PDF files directly.

4.Advance material waste simulation: for large patterns, marker simulation is required, with high-end silk fabric waste rate controlled at ≤15% (conventional styles ≤8%) to avoid production exceeding cost.

5.Mandatory quality tests: wash and rub tests must meet ISO 105 standard level 3.5 or above (high-end pajamas requirement), and silk materials require additional sweat stain colorfastness testing to ensure skin safety. (Testing items need to be clearly specified, as testing companies charge separately for different testing projects.)

[Production implementation: control alignment and compliance]

6.Sustainability requirements should be included in the tech pack: clearly incorporate GOTS/OEKO-TEX certification clauses into the process sheet and submit the fabric testing report 4 weeks in advance (to avoid production delays).

7.Jacquard capacity should be reserved in advance: high-end jacquard robes require a 2-week appointment for electronic looms and weavers to confirm the pattern complexity and loom parameters (e.g., warp density ≥ 120 ends/inch).

8.Incorporate alignment guidelines into the pattern design: indicate the standard for seam allowance pattern matching in the pattern diagram (e.g., stripe pajamas side seam error ≤ 2mm) to reduce sewing misalignment rates. The specific tolerance is related to the fabric used; usually, during the weaving process, fabric can produce twist. Knitted fabrics tend to have a larger degree of twist, while woven fabrics have less twist compared to knitted fabrics, so twist is a natural occurrence.

9.Data accumulation for small batch trials: After producing 100-200 samples, it is necessary to collect data such as color difference △E ≤ 1.5 and shrinkage rate ≤ 5% (for high-end cotton materials) to serve as the baseline for mass production.

Remark:The cost of small batch trials is usually higher than that of mass production. Taking fabric cutting as an example (data is for illustration purposes), the cost per cut is $10. In mass production, with fabric stacked 50 layers high and cutting 50 layers at a time, the cost allocated to each layer is only $0.2. In sample production, with fabric stacked 2 layers high and cutting 2 layers at a time, the cost allocated to each layer is $5. Under the same labor costs, the cutting cost for samples is 25 times higher than that for mass production ($5 divided by $0.2). For individual samples, such as prototypes or fitting samples, the fabric is only one layer, making the cost $10, which is 50 times higher than mass production ($10 divided by $0.2). Cutting is just one part of the garment-making process, which involves multiple steps. This example aims to illustrate the reasons for the higher costs associated with small batch trials, with the final charge determined by the factory.

[Long-term collaboration: Synchronizing trends and production capacity]

10.Establish a quarterly trend review mechanism: Share popular fabric patterns (e.g., vintage floral for Fall/Winter 2025) with the factory each quarter, and secure production capacity in advance (high-end silk printing capacity is limited and needs to be booked one month in advance).

Fabric patterns are the core competitiveness of high-end pajamas: they serve as an aesthetic expression of brand tone and are key to building craftsmanship barriers and enhancing product premium. A scientific sampling system combined with precise dyeing and printing process selection is the essential guarantee for transforming design ideals into bestselling products with premium capabilities.

PJGarment leverages its experience with over 30 international high-end brands such as SKIMS and Hanro to provide full-link support from fabric selection to mass production—especially with mature solutions in digital printing precision control, standardized color management, and sustainable small-batch production. Contact us for a free technical assessment and design sample service to quickly validate the feasibility of your designs.

FAQ:

1.What are the most popular fabric patterns?

Currently, popular fabric patterns in the pajama and loungewear sector mainly include small florals, subtle stripes, vintage paisley, and large-scale botanical prints. Seasonal changes and market preferences can influence their popularity, so it is recommended to make decisions based on region-specific sales data.

2.How to choose pattern for knitted fabrics?

Knitted fabrics have stretchability, and pattern types should avoid overly precise pattern matching requirements. Digital printing and reactive dyeing perform better on knits, and sample making should involve stretching before cutting pattern pieces for fitting to confirm any pattern distortion.

3.What is repeat in fabric patterns?

Repeat refers to the size of the pattern’s repeat unit (repeat size), which affects visual density and the arrangement of pattern pieces. The repeat size should match the garment’s block, and during the marker making phase, pattern pieces need to be simulated to control fabric utilization and pattern continuity.

4.How does pattern affect production cost?

Fabric patterns can affect multiple costs: printing process selection (digital vs. screen), number of colors, piece loss (caused by repeat), post-finishing processes (softeners or napping), and inspection costs. Complex or large-scale fabric patterns typically have a higher unit cost.

5.Can artisanal patterns be reproduced at scale?

Many hand-crafted or ethnic patterns (such as batik and ikat) can be reproduced in large-scale production using modern printing techniques or by combining special finishing (faux hand-made effect). The key is to thoroughly test the reproducibility of the hand-crafted effect during the sample making phase and establish quality tolerance.