OEM clothing manufacturing is a complex process that involves collaborating with manufacturers to create and produce clothing items. In this article, we will explore the role of Fabricantes de vestuário OEM and the benefits of working with them. We will also discuss how to choose the right OEM clothing manufacturer by considering various factors and asking important questions. Read on to discover the key takeaways from this insider’s guide to OEM clothing manufacturers.

Principais conclusões

- OEM clothing manufacturers play a crucial role in the clothing industry by providing design, production, and distribution services.

- Working with OEM clothing manufacturers can offer cost savings, faster production times, and access to specialized expertise.

- When selecting an OEM clothing manufacturer, consider factors such as their experience, production capabilities, and quality control processes.

- Ask potential OEM clothing manufacturers about their pricing structure, minimum order quantities, and communication channels.

- Remember to establish clear communication and expectations with your chosen OEM clothing manufacturer to ensure a successful partnership.

What is OEM Clothing Manufacturing?

Definition of OEM Clothing Manufacturing:

OEM (Original Equipment Manufacturer) clothing manufacturing refers to the process where a manufacturer produces garments based on the designs and specifications provided by another company, which then sells the finished products under its own brand name. Essentially, the brand outsources the production to the OEM manufacturer but retains the branding and marketing responsibilities.

Differences between OEM, ODM, and OBM:

- OEM (Original Equipment Manufacturer): The manufacturer produces clothing based on the brand’s designs and specifications. For example, a small fashion brand may design a new line of summer dresses and hire an OEM manufacturer to produce them.

- ODM (Original Design Manufacturer): The manufacturer provides design and production services. Brands can choose from existing designs or request custom modifications. For instance, a sportswear brand might select a pre-designed activewear set from an ODM and request specific color changes.

- OBM (Original Brand Manufacturer): The manufacturer not only produces but also designs and sells the products under its own brand name. An example is a well-known fashion house like Zara, which designs, manufactures, and sells its own clothing.

Advantages of OEM for Clothing Brands:

- Custo-eficácia: Brands can save on the costs associated with setting up and maintaining production facilities. For example, a startup fashion brand can focus its budget on marketing and retail rather than manufacturing.

- Access to Expertise: OEM manufacturers often have specialized knowledge and advanced technology. A luxury lingerie brand might benefit from an OEM manufacturer with expertise in delicate fabrics and intricate designs.

- Flexibility: Brands can scale production up or down based on demand without worrying about idle production lines. For instance, a seasonal clothing brand can increase production during peak seasons and reduce it during off-peak times.

By understanding OEM clothing manufacturing, brands can leverage these advantages to streamline their operations and focus on building their market presence.

The Role of OEM Clothing Manufacturers

Como Fabricantes de vestuário OEM, we play a crucial role in the fashion industry. Our primary responsibility is to produce clothing items based on the specifications provided by our clients. We work closely with brands and designers to bring their creative visions to life.

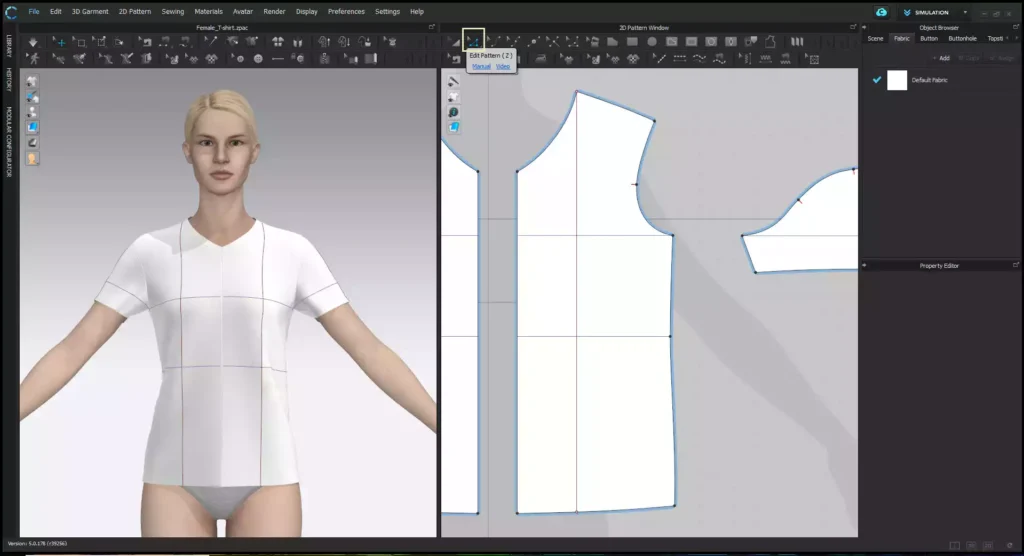

Our expertise lies in understanding the technical aspects of garment production, including fabric selection, pattern making, and sample development. We have a deep understanding of the manufacturing process and ensure that each garment meets the highest quality standards.

In addition to production, we also provide valuable input and guidance to our clients. We offer advice on cost-effective manufacturing techniques, suggest improvements to enhance the design and functionality of the garments, and help streamline the production timeline.

By partnering with us, brands and designers can focus on their core competencies, such as marketing and sales, while we take care of the manufacturing process. We are committed to delivering exceptional products that meet the unique needs and preferences of our clients.

Benefits of Working with OEM Clothing Manufacturers

Working with Fabricantes de vestuário OEM offers several advantages for businesses in the fashion industry.

Cost-Effectiveness and Scalability:

One of the primary benefits of using OEM clothing manufacturers is cost-effectiveness. Brands can avoid the significant capital expenditure required to set up and maintain their own production facilities. For example, a startup fashion brand can allocate its budget to marketing and retail operations rather than investing in expensive machinery and labor. Additionally, OEM manufacturers often benefit from economies of scale, allowing them to produce garments at a lower cost per unit. This cost efficiency can be passed on to the brand, making it easier to scale production as demand increases.

Access to Specialized Expertise and Technology:

OEM manufacturers typically possess specialized knowledge and advanced technology that brands may not have in-house. For instance, a luxury lingerie brand might partner with an OEM manufacturer renowned for its expertise in working with delicate fabrics and intricate lace designs. This access to specialized skills and cutting-edge technology ensures high-quality production and innovation in garment design and construction.

Flexibility in Design and Production:

Working with OEM manufacturers offers brands greater flexibility in design and production. Brands can easily adjust production volumes based on market demand without worrying about idle production lines. For example, a seasonal clothing brand can increase production during peak seasons and reduce it during off-peak times. Additionally, OEM manufacturers can accommodate custom design requests, allowing brands to experiment with new styles and trends without committing to large production runs.

Ability to Focus on Branding and Marketing:

By outsourcing production to OEM manufacturers, brands can concentrate on building their market presence and enhancing their brand identity. For example, a fashion brand can focus on creating compelling marketing campaigns, engaging with customers on social media, and expanding its retail footprint. This focus on branding and marketing can drive sales and foster customer loyalty, ultimately contributing to the brand’s long-term success.

Dica: When working with OEM clothing manufacturers, it is essential to establish clear communication channels and maintain a strong partnership to ensure smooth operations and successful outcomes.

Choosing the Right OEM Clothing Manufacturer

Factors to Consider When Selecting an OEM Clothing Manufacturer

When selecting an OEM clothing manufacturer, there are several important factors to consider. These factors will help ensure that you choose the right partner for your fabrico de vestuário needs.

1. Expertise and Experience: Look for a manufacturer that has extensive expertise and experience in the specific type of clothing you want to produce. This will ensure that they have the necessary knowledge and skills to meet your quality standards.

2. Production Capacity: Consider the production capacity of the manufacturer. Make sure they have the resources and capabilities to handle the volume of clothing you require. This will help prevent delays and ensure timely delivery.

3. Quality Control: Quality is crucial when it comes to clothing manufacturing. Look for a manufacturer that has strict quality control processes in place. This will help ensure that the final products meet your specifications and satisfy your customers.

4. Communication and Responsiveness: Effective communication is essential for a successful partnership. Choose a manufacturer that is responsive and communicates clearly and promptly. This will help avoid misunderstandings and ensure that your requirements are met.

5. Pricing and Cost: Consider the pricing and cost structure of the manufacturer. While it’s important to find a manufacturer that offers competitive pricing, be cautious of extremely low prices, as they may indicate compromised quality or hidden costs.

6. Ethical and Sustainable Practices: In today’s conscious consumer market, ethical and sustainable practices are increasingly important. Look for a manufacturer that follows ethical labor practices and uses sustainable materials and production methods.

7. Samples and Prototypes: Before committing to a manufacturer, request samples or prototypes of their work. This will allow you to assess the quality and craftsmanship of their products before making a decision.

Remember, selecting the right OEM clothing manufacturer is a crucial step in the success of your clothing brand. Take the time to thoroughly evaluate your options and choose a partner that aligns with your values and requirements.

Questions to Ask Potential OEM Clothing Manufacturers

As we evaluate potential OEM clothing manufacturers, there are several key questions that we should ask to ensure we make an informed decision:

- What is your minimum order quantity (MOQ)? Understanding the MOQ is crucial as it determines the feasibility of working with the manufacturer.

- What is your production capacity? It is important to know if the manufacturer has the capacity to meet our production needs and deadlines.

- What is your lead time for production? Knowing the lead time helps us plan our production schedule and ensure timely delivery of our products.

- Do you have experience working with similar products? Experience in manufacturing similar products can indicate the manufacturer’s expertise and understanding of our specific requirements.

- What quality control measures do you have in place? Ensuring that the manufacturer has robust quality control processes is essential to maintain the quality of our products.

- What are your pricing and payment terms? Understanding the pricing structure and payment terms helps us assess the financial feasibility of working with the manufacturer.

- Can you provide references or samples of your previous work? Requesting references or samples allows us to evaluate the manufacturer’s track record and the quality of their work.

By asking these questions, we can gather valuable information to make an informed decision when selecting an OEM clothing manufacturer.

Top OEM Clothing Manufacturers Around the World

Overview of Leading OEM Clothing Manufacturers in Different Regions:

OEM clothing manufacturers are spread across the globe, each offering unique advantages based on their location. Key regions include Asia, Europe, and North America.

OEM Clothing Manufacturers in Asia:

- China: Known for its large-scale production capabilities and cost-effectiveness. Pjgarment specializes in sleepwear and casual clothing, offering comprehensive services from design to delivery.

- Bangladesh: Renowned for its expertise in producing high-quality garments at competitive prices. DBL Group is a leading manufacturer known for its sustainable practices and production of knitwear.

OEM Clothing Manufacturers in Europe:

- Italy: Famous for luxury fashion and high-end craftsmanship. Marzotto Group offers premium quality textiles and garments, specializing in tailored suits and luxury fabrics.

- Portugal: Known for its high standards in quality and ethical manufacturing. P&R Texteis specializes in sustainable clothing and technical textiles.

OEM Clothing Manufacturers in North America:

- USA: Offers advanced technology and quick turnaround times. American Apparel Production Inc. is known for its high-quality basics and sustainable practices.

- Mexico: Provides cost-effective manufacturing with proximity to the US market. Kaltex specializes in denim and casual wear, offering a full range of services from fabric production to finished garments.

Highlight Specific Manufacturers Known for Certain Types of Clothing:

- Sleepwear: Pjgarment in China is renowned for its high-quality sleepwear, offering customization and innovative fabric options.

- Luxury Fashion: Marzotto Group in Italy is a leader in luxury fashion, providing bespoke tailoring and premium fabrics.

- Sustainable Clothing: P&R Texteis in Portugal focuses on sustainable and eco-friendly clothing, using organic materials and ethical production practices.

Tips for Building a Strong Relationship with Your OEM Manufacturer

Importance of Clear Communication and Regular Updates:

Clear communication is vital for a successful partnership with your OEM manufacturer. Establishing regular updates and maintaining open lines of communication can prevent misunderstandings and ensure that both parties are aligned. For example, a fashion brand can schedule weekly video calls with their OEM partner to discuss production progress, address any concerns, and make necessary adjustments.

Building Trust and Maintaining Transparency:

Trust and transparency are the foundations of a strong relationship. Sharing relevant information and being honest about expectations can foster mutual respect. For instance, a clothing brand should transparently share their sales forecasts and market feedback with the OEM manufacturer. This openness can help the manufacturer plan production more efficiently and align their efforts with the brand’s goals.

Collaborating on Product Development and Innovation:

Collaborating on product development can lead to innovative solutions and improved products. Engaging the OEM manufacturer in the design process can leverage their expertise and technical knowledge. For example, a sportswear brand might work closely with their OEM manufacturer to develop a new line of moisture-wicking fabrics, combining the brand’s vision with the manufacturer’s technical capabilities.

Addressing Issues Promptly and Effectively:

Addressing issues promptly and effectively is crucial for maintaining a positive relationship. When problems arise, it’s important to communicate them immediately and work together to find solutions. For instance, if a batch of garments has quality issues, the brand should notify the OEM manufacturer right away and collaboratively develop a plan to rectify the situation and prevent future occurrences.

Investing in Long-Term Partnerships:

Investing in long-term partnerships can yield significant benefits over time. Building a strong, enduring relationship with an OEM manufacturer can lead to better collaboration, improved product quality, and cost savings. For example, a brand that consistently works with the same OEM manufacturer can negotiate better terms, benefit from the manufacturer’s deep understanding of their needs, and achieve greater consistency in product quality.

Common Challenges and How to Overcome Them

Potential Challenges When Working with OEM Manufacturers:

Working with OEM manufacturers can present several challenges, including quality control issues, production delays, and miscommunication. For instance, a fashion brand might receive a shipment of garments that do not meet the agreed-upon quality standards, or experience delays that disrupt their supply chain.

Strategies for Overcoming Common Issues:

- Controlo de qualidade: Implementing rigorous quality control measures can help mitigate quality issues. For example, a brand can establish a detailed quality checklist and conduct regular inspections at various stages of production. Additionally, working with a third-party quality assurance service can provide an extra layer of oversight.

- Delays: To manage production delays, maintaining a buffer in the production schedule is crucial. For instance, a brand can set earlier deadlines for critical milestones to account for potential delays. Additionally, maintaining open communication with the OEM manufacturer can help identify and address any bottlenecks promptly.

- Miscommunication: Clear and consistent communication can prevent misunderstandings. Using project management tools and maintaining detailed documentation of all agreements and specifications can ensure that both parties are on the same page. Regular meetings and updates can also help address any issues before they escalate.

Importance of Contingency Planning and Risk Management:

Contingency planning and risk management are essential for navigating potential challenges. For example, a brand can develop a contingency plan that includes alternative suppliers and backup plans for critical production stages. This proactive approach can help minimize disruptions and ensure continuity in case of unforeseen issues.

Future Trends in OEM Clothing Manufacturing

Emerging Trends and Technologies in the OEM Clothing Industry:

The OEM clothing industry is rapidly evolving with the adoption of advanced technologies. Innovations such as automation, 3D printing, and AI-driven design are transforming manufacturing processes. For example, 3D knitting machines allow for seamless garment production, reducing waste and increasing efficiency.

Impact of Sustainability and Ethical Manufacturing Practices:

Sustainability and ethical manufacturing practices are becoming increasingly important. Consumers are demanding eco-friendly products, prompting manufacturers to adopt sustainable practices. For instance, Pjgarment in China focuses on using organic materials and reducing environmental impact through energy-efficient processes and waste minimization.

Predictions for the Future of OEM Clothing Manufacturing:

The future of OEM clothing manufacturing is likely to see a greater emphasis on customization and on-demand production. Technologies like AI-driven customization platforms will enable brands to offer personalized products at scale. Additionally, the industry will continue to prioritize sustainability, with a shift towards circular fashion models where garments are designed for reuse and recycling, minimizing waste and environmental impact.

Conclusão

In this guide, we explored the essentials of building a strong relationship with your OEM manufacturer, overcoming common challenges, and staying ahead of future trends. By fostering clear communication, trust, and collaboration, brands can achieve successful partnerships. Embracing sustainability and innovative technologies will shape the future of OEM clothing manufacturing. We encourage brands to consider OEM manufacturing for their clothing lines to leverage these benefits.

We invite you to share your experiences or ask questions in the comments below. Your insights can help others navigate their OEM manufacturing journey.

FAQs

What is an OEM clothing manufacturer?

An OEM clothing manufacturer is a company that produces clothing and apparel on behalf of other brands or companies. They specialize in manufacturing garments based on the specifications and designs provided by their clients.

What is the difference between OEM and ODM?

OEM (Original Equipment Manufacturer) produces products based on the client’s specifications, while ODM (Original Design Manufacturer) provides products designed by the manufacturer that clients can rebrand.

What are the benefits of working with an OEM clothing manufacturer?

Working with an OEM clothing manufacturer offers several benefits, including cost-effectiveness, access to specialized expertise, flexibility in production, and the ability to scale production capacity.

How do I find the right OEM clothing manufacturer for my brand?

Research potential manufacturers, check their credentials, request samples, and visit their facilities if possible.

How do I choose the right OEM clothing manufacturer?

When choosing an OEM clothing manufacturer, consider factors such as their experience, production capabilities, quality control processes, communication skills, and pricing. It is also important to assess their track record and reputation in the industry.

What factors should I consider when selecting an OEM clothing manufacturer?

Some important factors to consider when selecting an OEM clothing manufacturer include their production capacity, lead times, minimum order quantities, production capabilities, quality control processes, and their ability to meet your specific requirements.

What questions should I ask potential OEM clothing manufacturers?

When evaluating potential OEM clothing manufacturers, consider asking questions about their experience, production capabilities, quality control processes, pricing, lead times, minimum order quantities, and their ability to handle customization or special requirements.

What are the typical lead times for OEM clothing production?

Lead times vary but generally range from 4 to 6 weeks, depending on the complexity and volume of the order.

How can I ensure the quality of the clothing produced by an OEM manufacturer?

To ensure the quality of the clothing produced by an OEM manufacturer, it is important to establish clear quality standards and specifications, conduct regular inspections and audits, and maintain open communication with the manufacturer throughout the production process. Implement strict quality control measures, such as regular inspections and third-party audits. For instance, a brand can hire a quality assurance firm to conduct periodic checks during production. It may also be beneficial to request samples or prototypes before placing a large order.