OEM-fremstilling af tøj er en kompleks proces, der involverer samarbejde med producenter om at skabe og producere beklædningsgenstande. I denne artikel vil vi udforske den rolle, som OEM-producenter af tøj og fordelene ved at arbejde sammen med dem. Vi vil også diskutere, hvordan man vælger den rigtige OEM-tøjproducent ved at overveje forskellige faktorer og stille vigtige spørgsmål. Læs videre for at opdage de vigtigste ting fra denne insider-guide til OEM-tøjproducenter.

Det vigtigste at tage med

- OEM-tøjproducenter spiller en afgørende rolle i tøjindustrien ved at levere design-, produktions- og distributionstjenester.

- At arbejde med OEM-tøjproducenter kan give omkostningsbesparelser, hurtigere produktionstider og adgang til specialiseret ekspertise.

- Når du vælger en OEM-producent af tøj, skal du overveje faktorer som deres erfaring, produktionskapacitet og kvalitetskontrolprocesser.

- Spørg potentielle OEM-tøjproducenter om deres prisstruktur, minimumsbestillingsmængder og kommunikationskanaler.

- Husk at etablere klar kommunikation og forventninger med din valgte OEM-tøjproducent for at sikre et vellykket partnerskab.

What is OEM Clothing Manufacturing?

Definition of OEM Clothing Manufacturing:

OEM (Original Equipment Manufacturer) clothing manufacturing refers to the process where a manufacturer produces garments based on the designs and specifications provided by another company, which then sells the finished products under its own brand name. Essentially, the brand outsources the production to the OEM manufacturer but retains the branding and marketing responsibilities.

Differences between OEM, ODM, and OBM:

- OEM (Original Equipment Manufacturer): The manufacturer produces clothing based on the brand’s designs and specifications. For example, a small fashion brand may design a new line of summer dresses and hire an OEM manufacturer to produce them.

- ODM (Original Design Manufacturer): The manufacturer provides design and production services. Brands can choose from existing designs or request custom modifications. For instance, a sportswear brand might select a pre-designed activewear set from an ODM and request specific color changes.

- OBM (Original Brand Manufacturer): The manufacturer not only produces but also designs and sells the products under its own brand name. An example is a well-known fashion house like Zara, which designs, manufactures, and sells its own clothing.

Advantages of OEM for Clothing Brands:

- Omkostningseffektivitet: Brands can save on the costs associated with setting up and maintaining production facilities. For example, a startup fashion brand can focus its budget on marketing and retail rather than manufacturing.

- Access to Expertise: OEM manufacturers often have specialized knowledge and advanced technology. A luxury lingerie brand might benefit from an OEM manufacturer with expertise in delicate fabrics and intricate designs.

- Flexibility: Brands can scale production up or down based on demand without worrying about idle production lines. For instance, a seasonal clothing brand can increase production during peak seasons and reduce it during off-peak times.

By understanding OEM clothing manufacturing, brands can leverage these advantages to streamline their operations and focus on building their market presence.

OEM-producenter af tøjs rolle

Som OEM-producenter af tøjVi spiller en afgørende rolle i modebranchen. Vores primære ansvar er at producere beklædningsgenstande baseret på de specifikationer, som vores kunder giver os. Vi arbejder tæt sammen med brands og designere for at føre deres kreative visioner ud i livet.

Vores ekspertise ligger i at forstå de tekniske aspekter af tøjproduktion, herunder stofvalg, mønsterfremstilling og udvikling af prøver. Vi har en dyb forståelse af fremstillingsprocessen og sikrer, at hvert stykke tøj lever op til de højeste kvalitetsstandarder.

Ud over produktionen giver vi også værdifuldt input og vejledning til vores kunder. Vi tilbyder rådgivning om omkostningseffektive produktionsteknikker, foreslår forbedringer, der forbedrer tøjets design og funktionalitet, og hjælper med at strømline produktionstidslinjen.

Ved at samarbejde med os kan brands og designere fokusere på deres kernekompetencer, såsom marketing og salg, mens vi tager os af fremstillingsprocessen. Vi er forpligtet til at levere enestående produkter, der opfylder vores kunders unikke behov og præferencer.

Fordele ved at arbejde med OEM-producenter af tøj

At arbejde med OEM-producenter af tøj giver flere fordele for virksomheder i modebranchen.

Cost-Effectiveness and Scalability:

One of the primary benefits of using OEM clothing manufacturers is cost-effectiveness. Brands can avoid the significant capital expenditure required to set up and maintain their own production facilities. For example, a startup fashion brand can allocate its budget to marketing and retail operations rather than investing in expensive machinery and labor. Additionally, OEM manufacturers often benefit from economies of scale, allowing them to produce garments at a lower cost per unit. This cost efficiency can be passed on to the brand, making it easier to scale production as demand increases.

Access to Specialized Expertise and Technology:

OEM manufacturers typically possess specialized knowledge and advanced technology that brands may not have in-house. For instance, a luxury lingerie brand might partner with an OEM manufacturer renowned for its expertise in working with delicate fabrics and intricate lace designs. This access to specialized skills and cutting-edge technology ensures high-quality production and innovation in garment design and construction.

Flexibility in Design and Production:

Working with OEM manufacturers offers brands greater flexibility in design and production. Brands can easily adjust production volumes based on market demand without worrying about idle production lines. For example, a seasonal clothing brand can increase production during peak seasons and reduce it during off-peak times. Additionally, OEM manufacturers can accommodate custom design requests, allowing brands to experiment with new styles and trends without committing to large production runs.

Ability to Focus on Branding and Marketing:

By outsourcing production to OEM manufacturers, brands can concentrate on building their market presence and enhancing their brand identity. For example, a fashion brand can focus on creating compelling marketing campaigns, engaging with customers on social media, and expanding its retail footprint. This focus on branding and marketing can drive sales and foster customer loyalty, ultimately contributing to the brand’s long-term success.

Tip: Når man arbejder med OEM-tøjproducenter, er det vigtigt at etablere klare kommunikationskanaler og opretholde et stærkt partnerskab for at sikre en gnidningsløs drift og vellykkede resultater.

At vælge den rigtige producent af OEM-tøj

Faktorer, du skal overveje, når du vælger en OEM-producent af tøj

Når du vælger en OEM-producent af tøj, er der flere vigtige faktorer, du skal overveje. Disse faktorer vil hjælpe med at sikre, at du vælger den rigtige partner til din fremstilling af tøj behov.

1. Ekspertise og erfaring: Kig efter en producent, der har omfattende ekspertise og erfaring med den specifikke type tøj, du ønsker at producere. Det vil sikre, at de har den nødvendige viden og de nødvendige færdigheder til at opfylde dine kvalitetsstandarder.

2. Produktionskapacitet: Overvej producentens produktionskapacitet. Sørg for, at de har ressourcer og kapacitet til at håndtere den mængde tøj, du har brug for. Det vil hjælpe med at forhindre forsinkelser og sikre rettidig levering.

3. Kvalitetskontrol: Kvalitet er afgørende, når det kommer til tøjproduktion. Kig efter en producent, der har strenge kvalitetskontrolprocesser på plads. Det vil være med til at sikre, at de endelige produkter lever op til dine specifikationer og tilfredsstiller dine kunder.

4. Kommunikation og lydhørhed: Effektiv kommunikation er afgørende for et vellykket partnerskab. Vælg en producent, der er lydhør og kommunikerer klart og hurtigt. Det vil hjælpe med at undgå misforståelser og sikre, at dine krav bliver opfyldt.

5. Prisfastsættelse og omkostninger: Overvej producentens priser og omkostningsstruktur. Selvom det er vigtigt at finde en producent, der tilbyder konkurrencedygtige priser, skal du være forsigtig med ekstremt lave priser, da de kan indikere kompromitteret kvalitet eller skjulte omkostninger.

6. Etisk og bæredygtig praksis: I nutidens bevidste forbrugermarked bliver etiske og bæredygtige metoder stadig vigtigere. Kig efter en producent, der følger etiske arbejdsmetoder og bruger bæredygtige materialer og produktionsmetoder.

7. Prøver og prototyper: Før du binder dig til en producent, bør du bede om prøver eller prototyper af deres arbejde. Det vil give dig mulighed for at vurdere kvaliteten og håndværket af deres produkter, før du træffer en beslutning.

Husk, at valget af den rigtige OEM-tøjproducent er et afgørende skridt for dit tøjmærkes succes. Tag dig tid til grundigt at evaluere dine muligheder, og vælg en partner, der stemmer overens med dine værdier og krav.

Spørgsmål til potentielle producenter af OEM-tøj

Når vi vurderer potentielle OEM-producenter af tøj, er der flere vigtige spørgsmål, vi bør stille for at sikre, at vi træffer en informeret beslutning:

- Hvad er din mindste ordremængde (MOQ)? Det er afgørende at forstå MOQ, da det afgør, om det er muligt at arbejde med producenten.

- Hvad er din produktionskapacitet? Det er vigtigt at vide, om producenten har kapacitet til at opfylde vores produktionsbehov og deadlines.

- Hvad er jeres leveringstid for produktion? At kende leveringstiden hjælper os med at planlægge vores produktionsplan og sikre rettidig levering af vores produkter.

- Har du erfaring med at arbejde med lignende produkter? Erfaring med fremstilling af lignende produkter kan indikere producentens ekspertise og forståelse af vores specifikke krav.

- Hvilke kvalitetskontrolforanstaltninger har du på plads? Det er vigtigt at sikre, at producenten har robuste kvalitetskontrolprocesser for at opretholde kvaliteten af vores produkter.

- Hvad er jeres priser og betalingsbetingelser? At forstå prisstrukturen og betalingsbetingelserne hjælper os med at vurdere den økonomiske mulighed for at arbejde med producenten.

- Kan du give referencer eller eksempler på dit tidligere arbejde? Ved at bede om referencer eller prøver kan vi evaluere producentens track record og kvaliteten af deres arbejde.

Ved at stille disse spørgsmål kan vi indsamle værdifulde oplysninger, så vi kan træffe en informeret beslutning, når vi vælger en OEM-producent af tøj.

Top OEM Clothing Manufacturers Around the World

Overview of Leading OEM Clothing Manufacturers in Different Regions:

OEM clothing manufacturers are spread across the globe, each offering unique advantages based on their location. Key regions include Asia, Europe, and North America.

OEM Clothing Manufacturers in Asia:

- China: Known for its large-scale production capabilities and cost-effectiveness. Pjgarment specializes in sleepwear and casual clothing, offering comprehensive services from design to delivery.

- Bangladesh: Renowned for its expertise in producing high-quality garments at competitive prices. DBL Group is a leading manufacturer known for its sustainable practices and production of knitwear.

OEM Clothing Manufacturers in Europe:

- Italy: Famous for luxury fashion and high-end craftsmanship. Marzotto Group offers premium quality textiles and garments, specializing in tailored suits and luxury fabrics.

- Portugal: Known for its high standards in quality and ethical manufacturing. P&R Texteis specializes in sustainable clothing and technical textiles.

OEM Clothing Manufacturers in North America:

- USA: Offers advanced technology and quick turnaround times. American Apparel Production Inc. is known for its high-quality basics and sustainable practices.

- Mexico: Provides cost-effective manufacturing with proximity to the US market. Kaltex specializes in denim and casual wear, offering a full range of services from fabric production to finished garments.

Highlight Specific Manufacturers Known for Certain Types of Clothing:

- Sleepwear: Pjgarment in China is renowned for its high-quality sleepwear, offering customization and innovative fabric options.

- Luxury Fashion: Marzotto Group in Italy is a leader in luxury fashion, providing bespoke tailoring and premium fabrics.

- Sustainable Clothing: P&R Texteis in Portugal focuses on sustainable and eco-friendly clothing, using organic materials and ethical production practices.

Tips for Building a Strong Relationship with Your OEM Manufacturer

Importance of Clear Communication and Regular Updates:

Clear communication is vital for a successful partnership with your OEM manufacturer. Establishing regular updates and maintaining open lines of communication can prevent misunderstandings and ensure that both parties are aligned. For example, a fashion brand can schedule weekly video calls with their OEM partner to discuss production progress, address any concerns, and make necessary adjustments.

Building Trust and Maintaining Transparency:

Trust and transparency are the foundations of a strong relationship. Sharing relevant information and being honest about expectations can foster mutual respect. For instance, a clothing brand should transparently share their sales forecasts and market feedback with the OEM manufacturer. This openness can help the manufacturer plan production more efficiently and align their efforts with the brand’s goals.

Collaborating on Product Development and Innovation:

Collaborating on product development can lead to innovative solutions and improved products. Engaging the OEM manufacturer in the design process can leverage their expertise and technical knowledge. For example, a sportswear brand might work closely with their OEM manufacturer to develop a new line of moisture-wicking fabrics, combining the brand’s vision with the manufacturer’s technical capabilities.

Addressing Issues Promptly and Effectively:

Addressing issues promptly and effectively is crucial for maintaining a positive relationship. When problems arise, it’s important to communicate them immediately and work together to find solutions. For instance, if a batch of garments has quality issues, the brand should notify the OEM manufacturer right away and collaboratively develop a plan to rectify the situation and prevent future occurrences.

Investing in Long-Term Partnerships:

Investing in long-term partnerships can yield significant benefits over time. Building a strong, enduring relationship with an OEM manufacturer can lead to better collaboration, improved product quality, and cost savings. For example, a brand that consistently works with the same OEM manufacturer can negotiate better terms, benefit from the manufacturer’s deep understanding of their needs, and achieve greater consistency in product quality.

Common Challenges and How to Overcome Them

Potential Challenges When Working with OEM Manufacturers:

Working with OEM manufacturers can present several challenges, including quality control issues, production delays, and miscommunication. For instance, a fashion brand might receive a shipment of garments that do not meet the agreed-upon quality standards, or experience delays that disrupt their supply chain.

Strategies for Overcoming Common Issues:

- Kvalitetskontrol: Implementing rigorous quality control measures can help mitigate quality issues. For example, a brand can establish a detailed quality checklist and conduct regular inspections at various stages of production. Additionally, working with a third-party quality assurance service can provide an extra layer of oversight.

- Delays: To manage production delays, maintaining a buffer in the production schedule is crucial. For instance, a brand can set earlier deadlines for critical milestones to account for potential delays. Additionally, maintaining open communication with the OEM manufacturer can help identify and address any bottlenecks promptly.

- Miscommunication: Clear and consistent communication can prevent misunderstandings. Using project management tools and maintaining detailed documentation of all agreements and specifications can ensure that both parties are on the same page. Regular meetings and updates can also help address any issues before they escalate.

Importance of Contingency Planning and Risk Management:

Contingency planning and risk management are essential for navigating potential challenges. For example, a brand can develop a contingency plan that includes alternative suppliers and backup plans for critical production stages. This proactive approach can help minimize disruptions and ensure continuity in case of unforeseen issues.

Future Trends in OEM Clothing Manufacturing

Emerging Trends and Technologies in the OEM Clothing Industry:

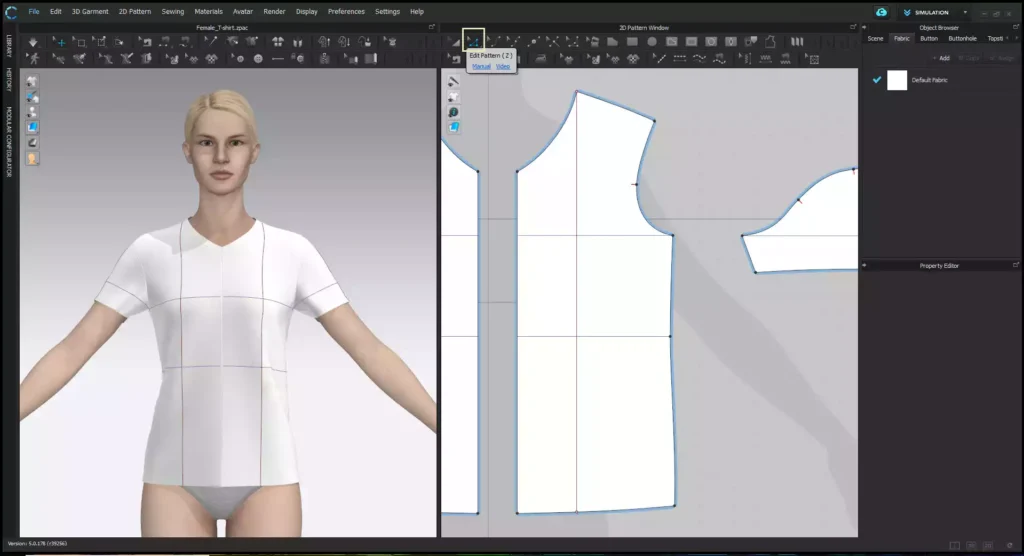

The OEM clothing industry is rapidly evolving with the adoption of advanced technologies. Innovations such as automation, 3D printing, and AI-driven design are transforming manufacturing processes. For example, 3D knitting machines allow for seamless garment production, reducing waste and increasing efficiency.

Impact of Sustainability and Ethical Manufacturing Practices:

Sustainability and ethical manufacturing practices are becoming increasingly important. Consumers are demanding eco-friendly products, prompting manufacturers to adopt sustainable practices. For instance, Pjgarment in China focuses on using organic materials and reducing environmental impact through energy-efficient processes and waste minimization.

Predictions for the Future of OEM Clothing Manufacturing:

The future of OEM clothing manufacturing is likely to see a greater emphasis on customization and on-demand production. Technologies like AI-driven customization platforms will enable brands to offer personalized products at scale. Additionally, the industry will continue to prioritize sustainability, with a shift towards circular fashion models where garments are designed for reuse and recycling, minimizing waste and environmental impact.

Konklusion

In this guide, we explored the essentials of building a strong relationship with your OEM manufacturer, overcoming common challenges, and staying ahead of future trends. By fostering clear communication, trust, and collaboration, brands can achieve successful partnerships. Embracing sustainability and innovative technologies will shape the future of OEM clothing manufacturing. We encourage brands to consider OEM manufacturing for their clothing lines to leverage these benefits.

We invite you to share your experiences or ask questions in the comments below. Your insights can help others navigate their OEM manufacturing journey.

Ofte stillede spørgsmål

Hvad er en OEM-producent af tøj?

En OEM-tøjproducent er en virksomhed, der producerer tøj og beklædning på vegne af andre mærker eller virksomheder. De specialiserer sig i at fremstille tøj baseret på de specifikationer og designs, som deres kunder leverer.

What is the difference between OEM and ODM?

OEM (Original Equipment Manufacturer) produces products based on the client’s specifications, while ODM (Original Design Manufacturer) provides products designed by the manufacturer that clients can rebrand.

Hvad er fordelene ved at arbejde med en OEM-producent af tøj?

At arbejde med en OEM-tøjproducent giver flere fordele, herunder omkostningseffektivitet, adgang til specialiseret ekspertise, fleksibilitet i produktionen og muligheden for at skalere produktionskapaciteten.

How do I find the right OEM clothing manufacturer for my brand?

Research potential manufacturers, check their credentials, request samples, and visit their facilities if possible.

Hvordan vælger jeg den rigtige OEM-producent af tøj?

Når du vælger en OEM-producent af tøj, skal du overveje faktorer som deres erfaring, produktionskapacitet, kvalitetskontrolprocesser, kommunikationsevner og priser. Det er også vigtigt at vurdere deres track record og omdømme i branchen.

Hvilke faktorer skal jeg overveje, når jeg vælger en OEM-producent af tøj?

Nogle af de vigtige faktorer, du skal overveje, når du vælger en OEM-producent af tøj, er deres produktionskapacitet, leveringstider, minimumsbestillingsmængder, produktionskapacitet, kvalitetskontrolprocesser og deres evne til at opfylde dine specifikke krav.

Hvilke spørgsmål skal jeg stille potentielle OEM-producenter af tøj?

Når du evaluerer potentielle OEM-tøjproducenter, bør du overveje at stille spørgsmål om deres erfaring, produktionskapacitet, kvalitetskontrolprocesser, priser, leveringstider, minimumsordremængder og deres evne til at håndtere tilpasninger eller særlige krav.

What are the typical lead times for OEM clothing production?

Lead times vary but generally range from 4 to 6 weeks, depending on the complexity and volume of the order.

Hvordan kan jeg sikre kvaliteten af det tøj, der produceres af en OEM-producent?

For at sikre kvaliteten af tøj produceret af en OEM-producent, it is important to establish clear quality standards and specifications, conduct regular inspections and audits, and maintain open communication with the manufacturer throughout the production process. Implement strict quality control measures, such as regular inspections and third-party audits. For instance, a brand can hire a quality assurance firm to conduct periodic checks during production. It may also be beneficial to request samples or prototypes before placing a large order.